Respect for your privacy is our priority

The cookie is a small information file stored in your browser each time you visit our web page.Cookies are useful because they record the history of your activity on our web page. Thus, when you return to the page, it identifies you and configures its content based on your browsing habits, your identity and your preferences.

You may accept cookies or refuse, block or delete cookies, at your convenience. To do this, you can choose from one of the options available on this window or even and if necessary, by configuring your browser.

If you refuse cookies, we can not guarantee the proper functioning of the various features of our web page.

For more information, please read the COOKIES INFORMATION section on our web page.

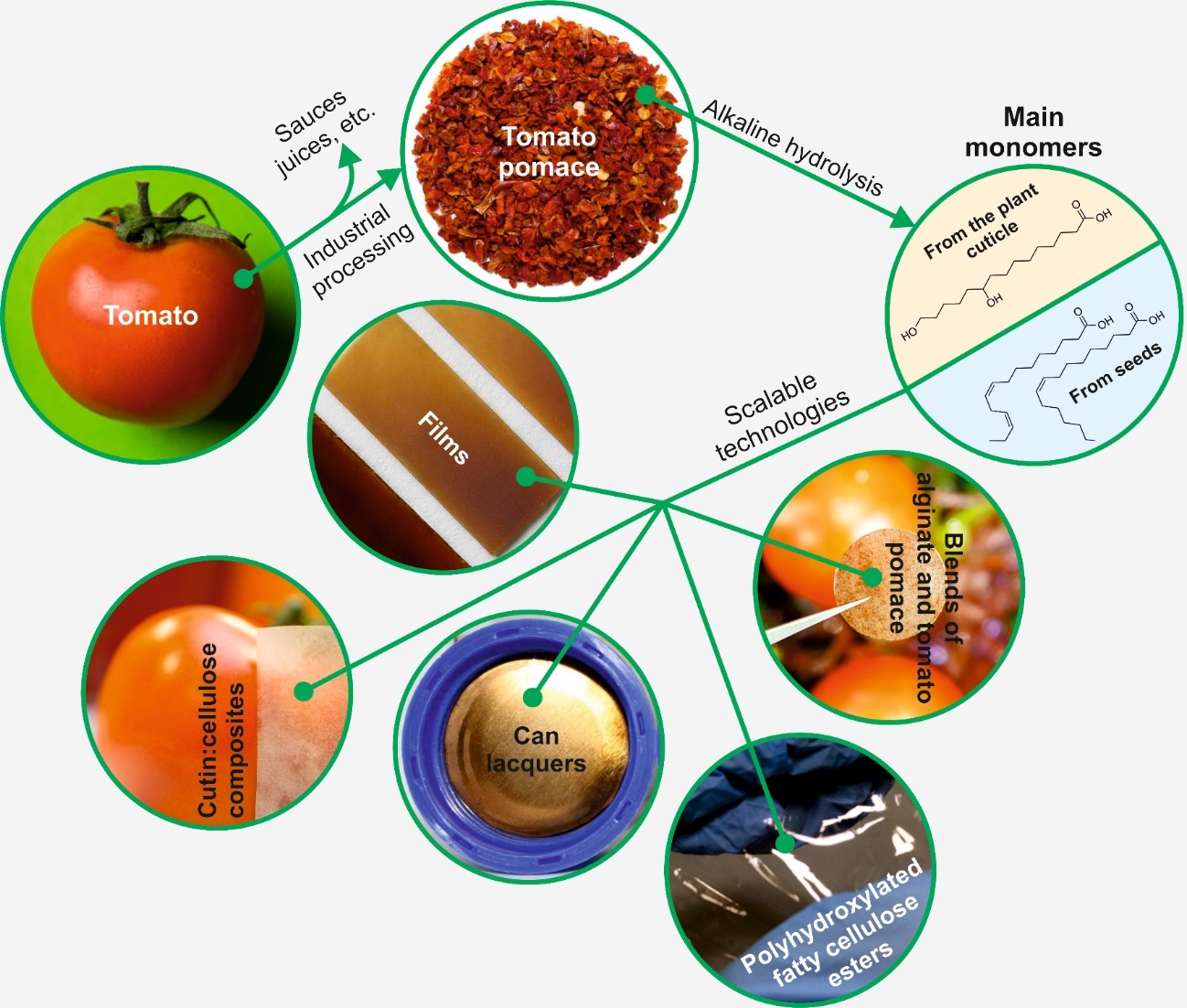

The researchers extracted cellulose from the tomato leaves, stems, and skin that are discarded in the canning industry after making tomato paste, sauce or ketchup. Researchers used these remains to create a robust and transparent film or plastic wrap that can have multiple applications, stated Institute of Subtropical and Mediterranean Horticulture (IHSM) researcher, Jose Alejandro Heredia, who works with the cellulose obtained from these remains to create a material capable of being modified with antibacterial bioactive substances and antioxidants that have properties for food packaging and that, in addition, would degrade in a minimum time compared to plastic containers.

The researchers extracted cellulose from the tomato leaves, stems, and skin that are discarded in the canning industry after making tomato paste, sauce or ketchup. Researchers used these remains to create a robust and transparent film or plastic wrap that can have multiple applications, stated Institute of Subtropical and Mediterranean Horticulture (IHSM) researcher, Jose Alejandro Heredia, who works with the cellulose obtained from these remains to create a material capable of being modified with antibacterial bioactive substances and antioxidants that have properties for food packaging and that, in addition, would degrade in a minimum time compared to plastic containers. These products will offer the same benefits as those made with petroleum-derived plastics, but will be biodegraded into non-toxic substances, thus avoiding the problem of collection and disposal after use. The physical properties of these products will be designed to be equivalent to those of common plastics through environmentally friendly chemical modifications. Finally, the environmental and economic sustainability of bioplastics production will be evaluated by determining the environmental impact through life cycle analysis and production costs, respectively.

These products will offer the same benefits as those made with petroleum-derived plastics, but will be biodegraded into non-toxic substances, thus avoiding the problem of collection and disposal after use. The physical properties of these products will be designed to be equivalent to those of common plastics through environmentally friendly chemical modifications. Finally, the environmental and economic sustainability of bioplastics production will be evaluated by determining the environmental impact through life cycle analysis and production costs, respectively.