Interview of David Page, Research Fellow with the INRA (SQPOV Unit)

Ever since Henry John Heinz in 1869 – and maybe even before the creation of what was to become that symbol of the world food sector – operators of the tomato processing industry have done their best to improve the quality of their products, their profitability, their production conditions, their image and their impact on their surroundings, whilst satisfying requirements within the economic, social, environmental and technical constraints of the sector.

Whether in the fields or in factories, a number of these major changes have been carried out in an empirical way, on the basis of experience. Others have required the help of science and researchers. Sometimes, industry has expressed needs that it hoped would be satisfied by scientific research. At other times, science has actually double-guessed production and gone ahead with the implementation of innovative tools. In all cases, the progress accomplished has been aimed at delivering the industry from specific constraints in order to provide it with more control and new possibilities in terms of procedures, products, technical itineraries, and sometimes costs.

The context of the relationship between industry and research

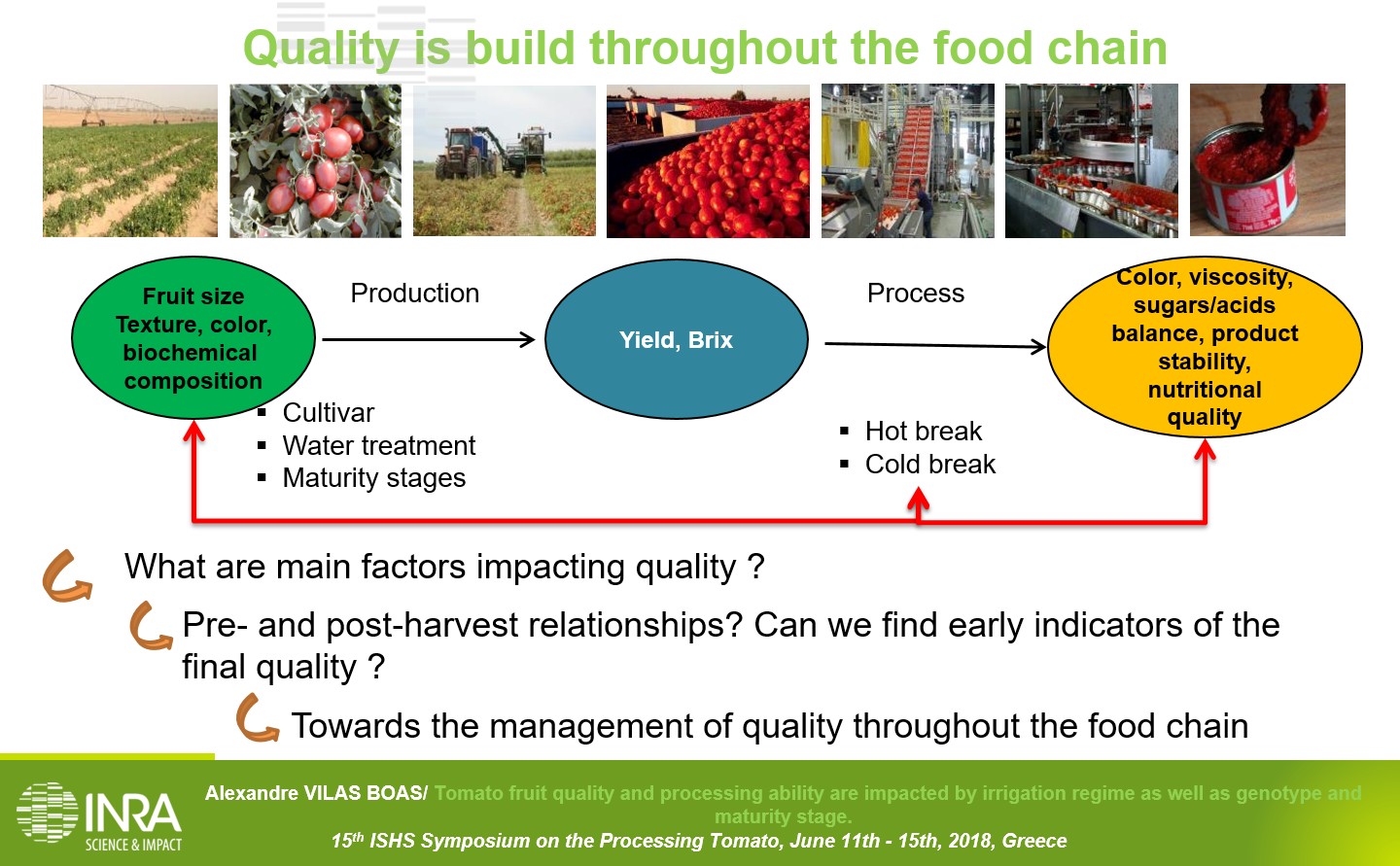

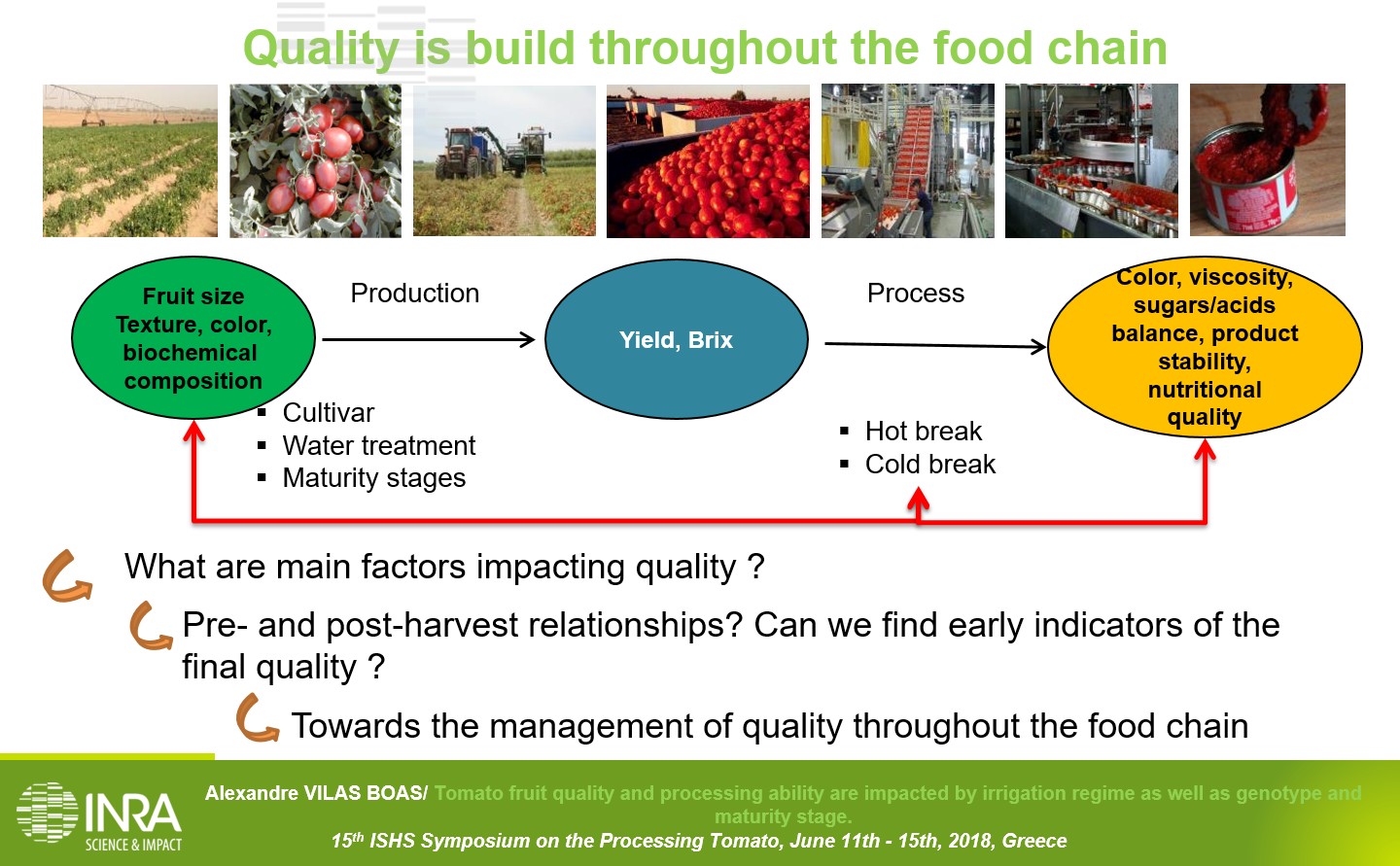

For David Page, research fellow of the SQPOV unit (Safety and Quality of Plant-Based Products) of the French INRA research institute in Avignon, the concerns of processors have for a long time no longer been focused merely on cost reduction, which is a target that is relatively easy to reach for anyone willing to compromise on quality, and which does not require any great assistance from scientific research. The researcher has observed that, "today, economy is no longer the only logic at play, and other concerns have also become vital: adapting to climate conditions, reducing agricultural inputs (water/pesticides, etc.), and supplying products that meet the strict technological targets set by processors. But there is very little knowledge available about the impact of cultivation practices on the technological qualities of products. Take for example, a ravioli manufacturing processor: the tomato sauce that is used to fill the cans must meet two objectives. The role it plays in the whole area of taste is essential, but it must also comply with a number of technological requirements: its water content must be specifically adjusted with regard to the ideal final texture of the ravioli, and it must correspond to the expectations of both the processor and the consumer. In the end, it is a very complex question, because the texture of the ravioli does not exclusively depend on the water content of the covering sauce, but also on the way that the sauce releases its water. And various phenomena known to researchers can alter the way that water binds with the sauce or becomes "releasable" to be absorbed by the pasta... For scientific research, the main focus needs to be on such details. When they are defined and understood, they can provide information for factories, then also further upstream for growers in the fields, regarding the more technical quality targets that can then be translated into selection targets for genetics specialists. Today, science knows how to work at this level of detail. For example, nuclear magnetic resonance is a way of measuring certain degrees of bonding between water and its matrix. Faced with this type of question, research often knows how to measure the phenomena, but in order to change scientific research questions into industrial quality targets, what is required is a shift in the way these questions are being asked and in the language used, in order to extend the vocabulary of the dialogue between processors and researchers. In particular, it is essential that we break free of the "Brix system", which is known to be insufficient in managing the daily running of a processing plant, all the more so for the fact that there is a disconnect between Brix, soluble solids and viscosity of the product for sale. In this regard, the recent thesis research carried out by Alexandre Vilas Boas, under the joint leadership of the INRA, the SONITO, the CTCPA …, has provided some strong results."

Tomato News: In this context, how should we consider the issue of the way our industry's main product – tomato paste, a product that is actually very technical – is valued almost exclusively on the basis of Brix? Are we to understand, in the light of this recent research, that the industry still does not have the adequate means to comprehend the fine points of the phenomena occurring in the factories?

David Page: "This is only partly true. Experience remains an important value, and we must continue to listen to people who "know that there is a link between Brix and viscosity because they have seen it and observed it". With tomato varieties that have been in use for several seasons, with well-established crops and normal weather conditions, there is an acknowledged link and it justifies the decisions taken in the management of processing operations. But the conditions that surround cultivation and processing now change very quickly: we are still ignorant of most of the consequences of global warming on product quality, and this is a problem in this context, leading to major and repeated variations in the way that raw materials behave in the factory. These exceptional situations will soon be part of the norm and we will need to have learned how to deal with these exceptional circumstances in order to manage the relationship between Brix and texture."

TN: So this means that we must enhance our control of the processes in order to make the best use possible, as quickly as possible, of each kilo of raw material that enters the factory, thanks to the technical characteristics of our products...

The Brix-viscosity dilemma

DP: "In addition to the fact that we are already and increasingly dealing with major changes, it is important to understand that the viscosity sold by processors, which is part of the basic commercial features of this industry, has for far too long been "imposed" rather than "chosen". In these conditions, optimizing the value of our products remains difficult because leverage handles are few and imperfect. When a processor is faced with the viscosity issue, he corrects the process by increasing the concentration level, which leads in turn to a drop in profitability for his operation. The final product sold has the correct viscosity, but it contains more soluble solids, has required more energy, and has ended up costing more than expected. There is a basic difference between the viscosity that is obtained by increasing the soluble solids content and the viscosity intrinsically produced by the fruit, a real difference between the transformations resulting from the process and those that are inherent to the tomato variety that was selected for planting.

There are many different definitions and appreciations of viscosity and they depend on a number of features that make up a complex sensation: some products are smooth and buttery, others are more pasty, some can be elastic or hard, while others are sticky, fluid, heavy... Science knows how to qualify and quantify a large proportion of these properties, as well as identifying the physical and chemical phenomena, and a number of biochemical processes responsible for the different textures like the transformation of pectins. This is possible notably thanks to the work of American scientists like Diane Barrett who described the finer alterations in textures and other properties in the "tomato" matrix somewhere between 2000 and 2005, or of the teams led by Marc Hendrickx in Leuven in Belgium, who spent a lot of time working on these topics. But the scientific contribution has nonetheless not resulted in the possibility of making varietal selections based on the type of pectin produced, for example. This stage of the decision-making process must be clarified, because there are wide variations around the structures of these pectins, and the reactions to processing procedures can be expressed in many different ways."

TN: So it is necessary to go well beyond the heat treatments that have been in use for decades – Cold Break and Hot Break – in order to understand the product, to manage the process and reach the final intentional target in terms of viscosity?

DP: "We have known for a long time that the Bostwick is a very empirical measurement – not even of viscosity, but of the consistency of a product. This consistency is the result of the coming together of several characteristics, among which are the viscosity of the serum, the interactions between the particles contained in this serum, and the sizes and shapes of these particles, which induce different rheological behaviors... All of these quality criteria must be requalified with regard to the different extremely fine-tuned approaches that we use in order to describe texture. The necessary equipment exists, and is probably already in use in a number of companies that have been able to anticipate these approaches. Brix or Bostwick values are insufficient to characterize the product, and these new broader approaches, which are also more comprehensive, represent the basis on which we need to rebuild the interactions between researchers and processors."

TN: Isn't equipment already available in other sectors of the food industry that could be reasonably put to use in our factories?

DP: "Viscometers, rheometers, texturometers... these are all affordable pieces of equipment that can provide other "measurements" linked to viscosity that are more precise than simply measuring the flow rate in a conduit positioned at a downward angle... The Bostwick still features among the industry standards because it is used in the context of trade, but other industrial sectors (like cosmetics, for example) use other terms to describe viscosity, because other approaches and other forms of equipment allow for different "scales" to be used."

TN: Doesn't the Bostwick's advantage of being intuitive, easy to comprehend and simple to implement explain its longevity within the industry?

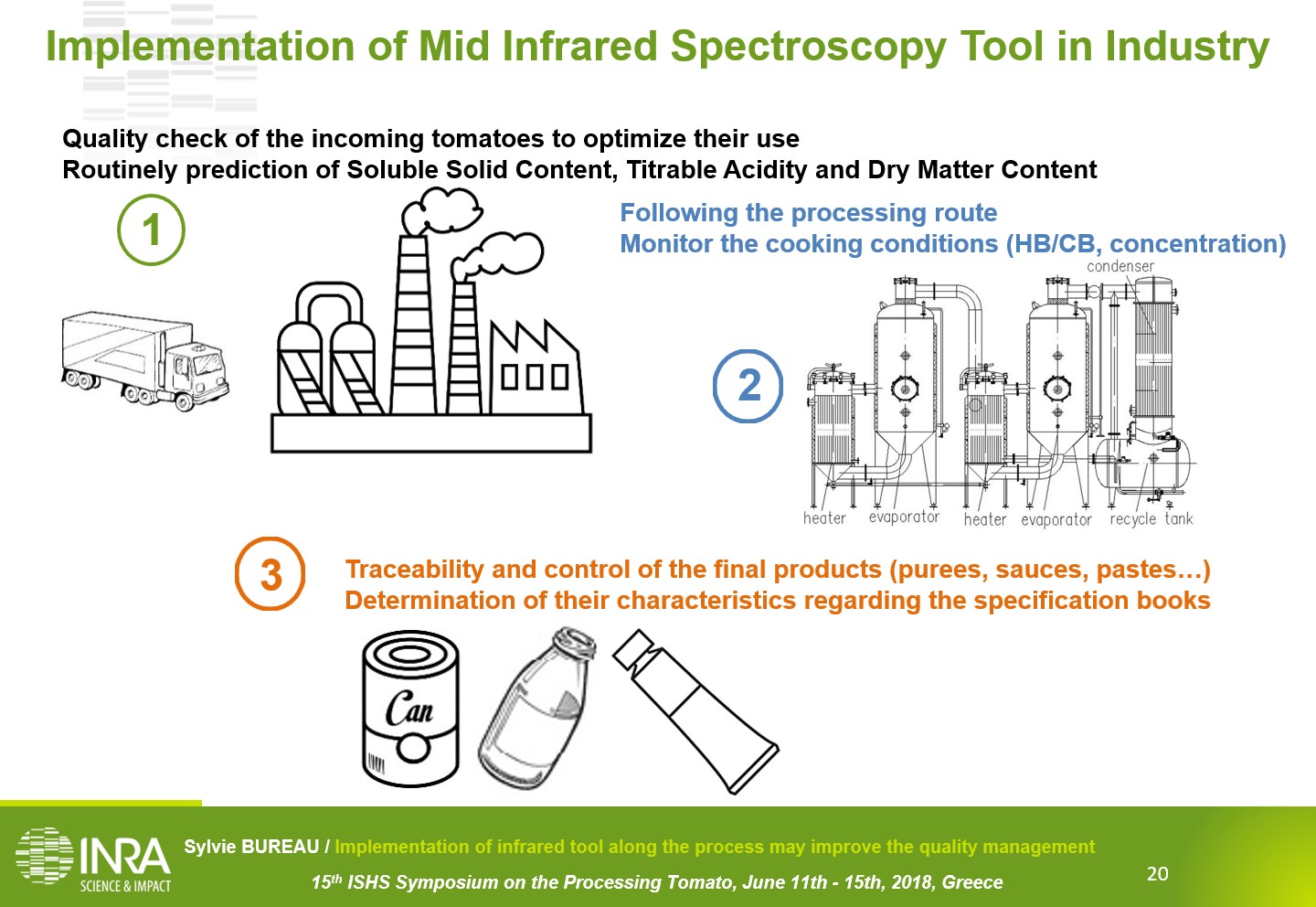

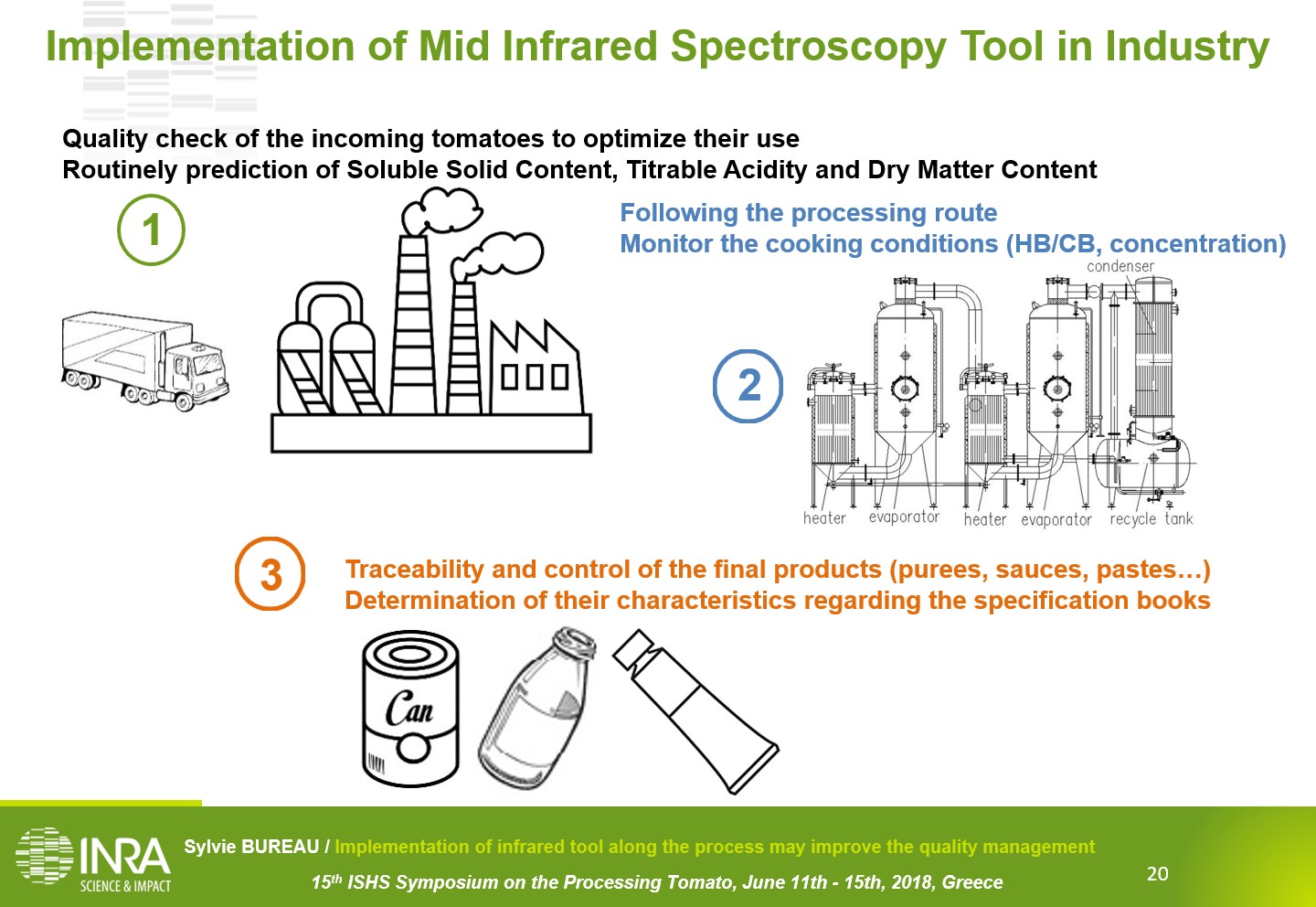

DP: "Indeed, that is the case. It is an apparently simple tool that measures consistency in an intuitive way. Nonetheless, it needs to be used according to very strict precautions if the measurement is to be reproduced elsewhere (no difference in temperature, perfectly dry equipment) and it can only be used in qualifying products within a certain range of viscosity. These limitations sometimes lead to discrepancies between the measurements carried out by different labs, or between those of a supplier and a client. Modern tools provide measurements that are easier to reproduce. Nonetheless, taking measurements according to a physical scale in a product remains a long process and is not very compatible with routine controls. Scientists have understood this need for speedy reactivity and can now offer not only other equipment, but other approaches that are more predictive, and these include infrared spectroscopy, which can provide satisfactory responses in terms of methods and measurements for our industrial context. Take, for example, a grading station, at the reception end of the processing plant. The situation requires the direct evaluation of quality in a context of responsibility that is likely to cause criticism from growers, but the product needs to comply with factory requirements, so decisions must be rapid and reliable. There are only a few minutes available for expressing a definitive diagnosis of the raw materials being receptioned. However, today, operators only have at their disposal measurements of the level of ripeness, of plant-health status and of average Brix levels taken on a sample of raw materials, whereas infrared could predict not only the Brix level, but also the actual soluble solids content and titratable acidity. Given the results obtained from experiments, it can reasonably be supposed that other calibrations could predict other quality attributes like the content of sugars or acids, and identify which types of tomato are best suited for specific manufacturing needs (pastes, peeled tomatoes, etc.). The grading process is intended to help take decisions when the raw materials do not match the expectations of the factory, whereas in fact, a large part of this decision, which concerns the complete itinerary from the seeds to the packaged conditioned product and the ultimate itinerary taken by the fruit, has been prepared over a six-month period, with decisions regarding variety, planting conditions, the technical itineraries used, and programming of both crops and processing operations. Installing a process based on infrared would be a way of rationalizing this stage, making it more objective, enhancing the value of products and identifying non-standard products".

Facilitating the management of "abnormal situations"?

"Such "abnormal" situations are increasingly frequent occurrences due to changes in production conditions linked to weather, pedology, the environment, etc. The increase in organic products, which are by nature more variable, contributes to this situation. In order to understand these "exceptions" and deal with the raw materials, it is necessary to be able to diagnose at an early stage when and in what circumstances the crops stopped following the normal pattern and possibly anticipate or delay the harvest, redirect a shipment towards a different manufacturing line or adjust processing operations. Throughout the production process, research must be able to draw up a diagnosis of the qualities being tracked. Today, thanks to infrared techniques, it has been clearly demonstrated that it is possible to obtain a diagnosis of soluble solids levels and to differentiate between levels of ripeness, but this technology is still virtually ignored by the industry. It is perfectly possible that tomorrow, research will allow operators to track specific characteristics by using spectral data to identify the state of the pectins found in the fruit and their influence on texture. In order to do that, it is necessary to acquire knowledge regarding their molecular composition and their dosage, but also their state of hydration or degradation, the extent to which they are affected by the pectinolytic enzymes in the fruit, and their capacity to form a gel. Rapid analysis tools like infrared could be relevant because pectic components are polymers that have clear infrared signatures.

Spectral methods (like infrared) provide a link between two different types of measurements. Firstly, it allows a particularly accurate characterization of phenomena that lead to quality variations, like the role of pectins that are present in the form of polymers of varying lengths and that demonstrate varying capacities to agglomerate and form gels affecting viscosity. In practice, this fine-tuned knowledge helps to explain, for example, why diluting a high-viscosity triple-concentrated purée makes the product lose many of its original characteristics of viscosity. And secondly, overall measurements of the quality of products or of raw materials means that reliable models can be drawn up that can quantify and monitor the evolution of phenomena, while linking them to prediction models that make them increasingly effective.

Isolating pectins and accurately characterizing them in tomato products throughout the value chain (from initial juice right up to the final sauce) can lead, in the end, to mechanistic models that are able to predict the quality of finished products on the basis of data measured in the raw materials. This provides industry with a tool that can predict as soon as the fruit enters the factory which varieties and which shipments may not provide satisfactory results after processing."

TN: In the case of a factory equipped with several lines used for different types of processing, can infrared analysis contribute to an earlier and improved redirection of non-standard raw materials towards the most suitable lines in terms of targets of viscosity, color, etc.?

DP: "It is already acknowledged that using infrared when shipments arrive at the factory can predict parameters that are likely to help take early decisions regarding the orientation of good quality fruit towards higher added-value industrial processes. We can be reasonably optimistic regarding the capacity to calibrate this tool with a view to obtaining predictions based on features of viscosity or color, providing a response in under a minute. Given the work already carried out and the extent of our knowledge, infrared has already demonstrated its usefulness in predicting the levels of real soluble solids and the balance between sugars and acidity agents. Clearly, a number of companies are currently investing in these new approaches, and researchers, particularly in California, Spain and France, are working on developing these techniques."