Respect for your privacy is our priority

The cookie is a small information file stored in your browser each time you visit our web page.Cookies are useful because they record the history of your activity on our web page. Thus, when you return to the page, it identifies you and configures its content based on your browsing habits, your identity and your preferences.

You may accept cookies or refuse, block or delete cookies, at your convenience. To do this, you can choose from one of the options available on this window or even and if necessary, by configuring your browser.

If you refuse cookies, we can not guarantee the proper functioning of the various features of our web page.

For more information, please read the COOKIES INFORMATION section on our web page.

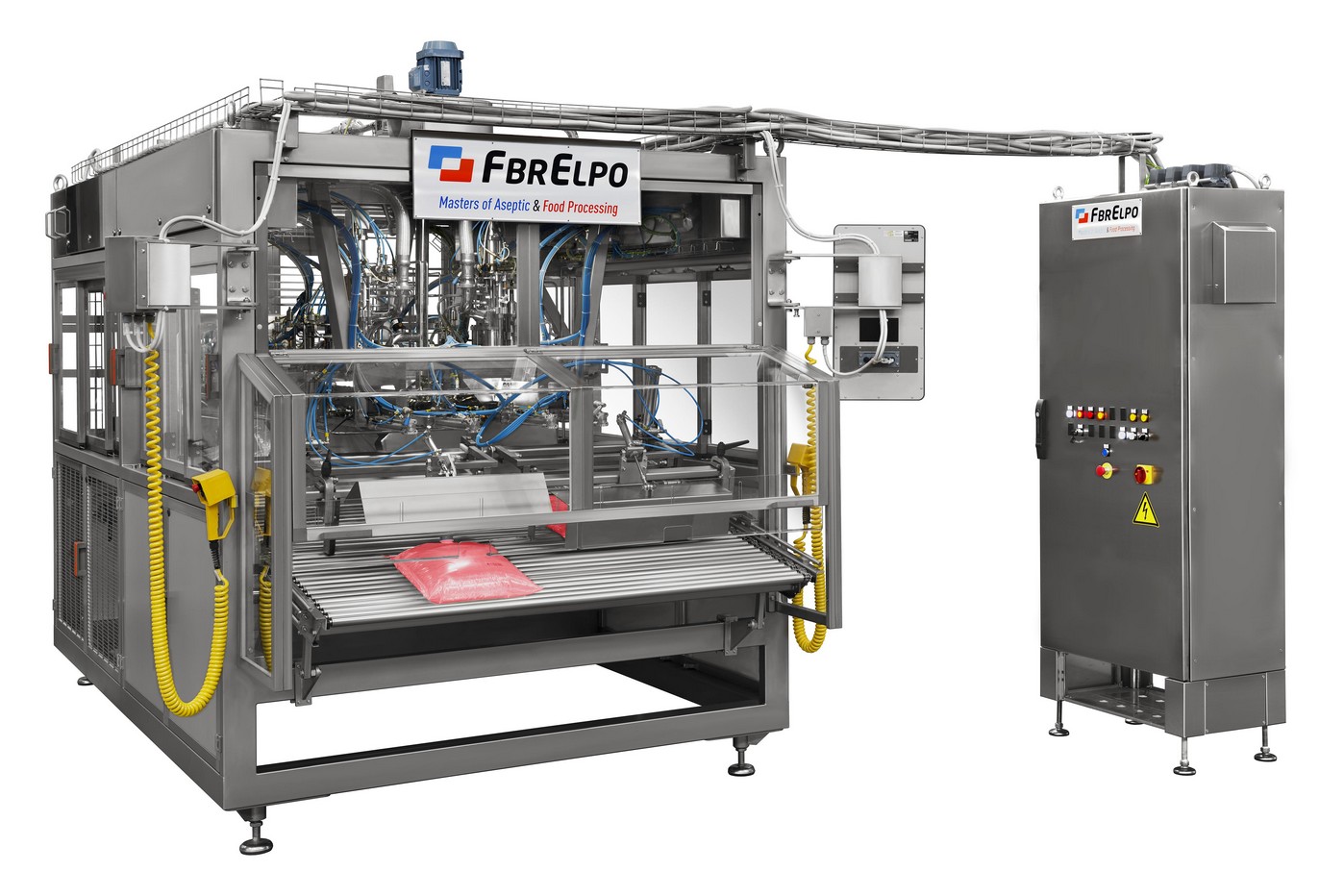

With over 700 aseptic installations sold worldwide, FBR ELPO is considered a leading company for the manufacturing of lines, machines and automatic and semiautomatic aseptic fillers, easy to use and of high quality. FBR ELPO’s aseptic fillers are extremely performing for liquid, pasty and concentrated products as well as for products with pieces, based on tomato, fruit, yogurt, milk and its by-products.

With over 700 aseptic installations sold worldwide, FBR ELPO is considered a leading company for the manufacturing of lines, machines and automatic and semiautomatic aseptic fillers, easy to use and of high quality. FBR ELPO’s aseptic fillers are extremely performing for liquid, pasty and concentrated products as well as for products with pieces, based on tomato, fruit, yogurt, milk and its by-products. The new filler is ideally used for handling the pre-sterilized bags with caps from 1 to 20 liters, with precut continuous module. It is suitable for filling the low and high acid products, such as milk, milk-shake, juices in general, purees, fruit and tomato concentrates, citrus juices and concentrates, tomato pulp, pizza sauce, physiological solutions, fertilizers and others.

The new filler is ideally used for handling the pre-sterilized bags with caps from 1 to 20 liters, with precut continuous module. It is suitable for filling the low and high acid products, such as milk, milk-shake, juices in general, purees, fruit and tomato concentrates, citrus juices and concentrates, tomato pulp, pizza sauce, physiological solutions, fertilizers and others. Like the other FBR ELPO filling machines, the new Mod. Mustang can also handle any kind of bag/ cap / spout available on the Bag-In-Box market, including those equipped with product emptying valves and taps, particularly suitable for dispensers, including those equipped the spouts with flexible hose for dispenser. Spouts can be “short neck” or “long neck type”, placed in the center or in the corner of the bag.

Like the other FBR ELPO filling machines, the new Mod. Mustang can also handle any kind of bag/ cap / spout available on the Bag-In-Box market, including those equipped with product emptying valves and taps, particularly suitable for dispensers, including those equipped the spouts with flexible hose for dispenser. Spouts can be “short neck” or “long neck type”, placed in the center or in the corner of the bag.