Luca Sandei, Carlotta Stingone, Rosanna Vitelli SSICA – Research Foundation

Parma – Italy

Background

Innovation and technology have been the primary concerns of the SSICA since it was established in 1922. In recent years, specific research projects have been focused on topics related to the satisfaction of constantly changing consumer requirements and to meeting the demand for Italian industrially processed products.

Tomatoes have been at the heart of SSICA R&D programs since the beginning of the research programs foundation and, above all, have become a fundamental component of the modern diet worldwide. In fact, tomato is consumed daily both as a fresh product and as a commercially available stabilized processed product thanks to increasingly advanced industrial conditioning operations.

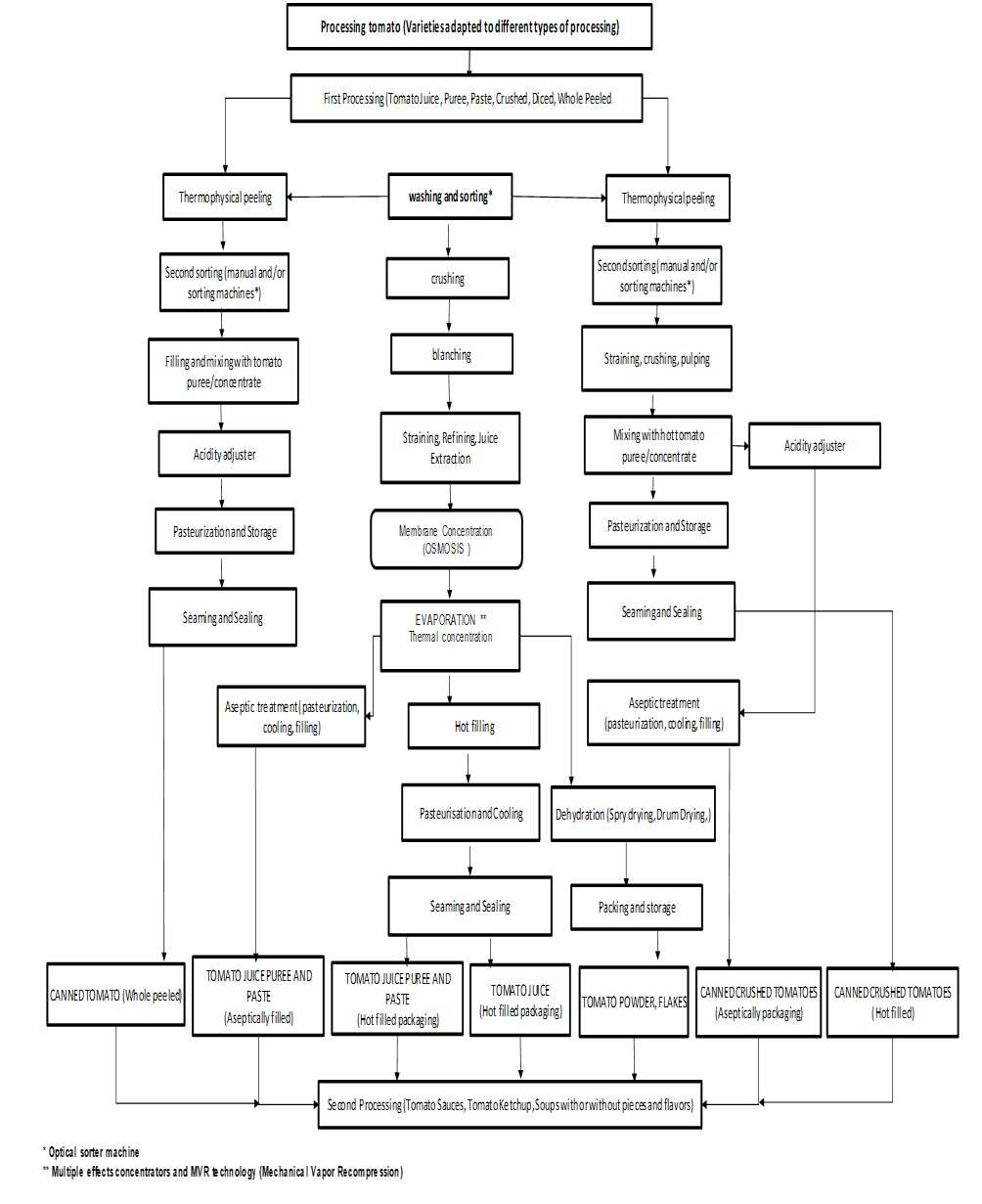

The long history of the Italian processing tomato industry explains the richness and diversity of differentiated procedures. These are based on several processing operations that follow two main processes. For the first one, tomatoes are processed into finished or semi-finished industrial products (tomato juice, purees, paste, diced, whole-peeled and unpeeled). In a second processing stage (reprocessing), products are turned into the final finished commercial formulated products like tomato sauces, soups, ketchups, pizza toppings and others. (Fig. 1)

Fig 1. Flow chart of tomato-processing unitary operations

Nutritional quality and health benefits of tomato

The various nutrients and "non-nutrients" (phytochemicals) naturally contained in the fresh fruit and vegetables are fundamental for human health. In the case of tomatoes, it has been scientifically demonstrated that the bioactive compounds naturally present in the fruit (which is particularly consumed in the context of Mediterranean dietary habits) contribute to a synergistic protective effect on human health.

As for the physical-chemical and sensory composition of fresh tomatoes, it has been proved that they are deeply influenced by several variables: a wide range of species, stage of ripeness, year of growth, climatic conditions, light, temperature, soil, fertilization, irrigation, and various other important factors of cultivation, handling and storage.

The average composition of fresh tomatoes (ripe fruit) is made up of water by more than 92%, and consequently, solids content represents between 4.5% and 8%. Nevertheless, in mature tomatoes, the dry matter content is mainly made up of sugars (~50%), organic acids (>10%), minerals (8%) and pectins (~7%). Nutritionally, the tomato is a good source of many components, including reducing sugars (principally glucose and fructose), organic acids (citric, malic and ascorbic acid), antioxidant compounds (carotenoids and phenols), vitamins and minerals (essentially potassium). Pectins, arabinogalactans, xylans, arabinoxylans and cellulose are the major polysaccharides. Citric acid is the most abundant organic acid (~0.60 g*l-1), followed by malic acid (~0.20 g*l-1).

Regarding the flavor of the fruit and the infinite ways it can be used in domestic kitchens and HoReCa settings, tomatoes present very interesting wide-ranging possibilities, thanks to their main physical-chemical and sensory components, which in recent years have been investigated by researchers carrying out experimental studies.

Based on acknowledged literature sources, the five primary sensations of taste are sourness, saltiness, sweetness, bitterness and umami. Salty and sour tastes show a much closer correlation with structure than do sweet and bitter tastes. The main sugars responsible for tomato sweetness are glucose and fructose; this latter component has a more important impact on sweet taste than glucose. As regards sourness, tomatoes contain mainly citric and malic acids, which are directly connected with this sensation. Moreover, citric and malic acids are also directly involved in the perception of saltiness, and the ratio of the citric to malic acids is highly influenced by the stage of ripeness.

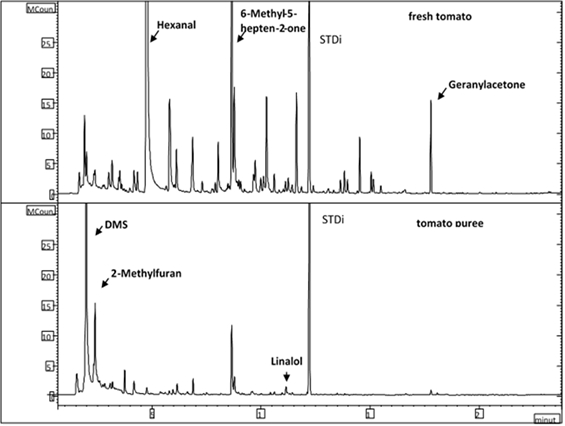

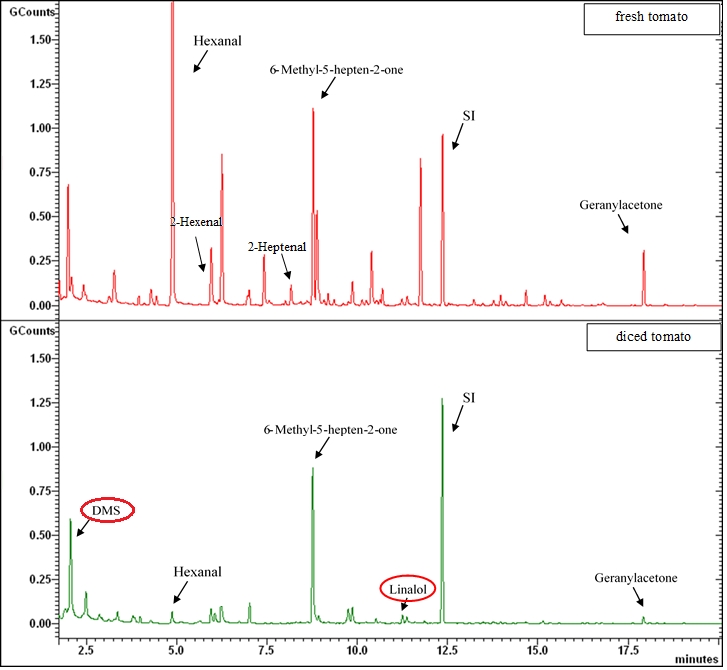

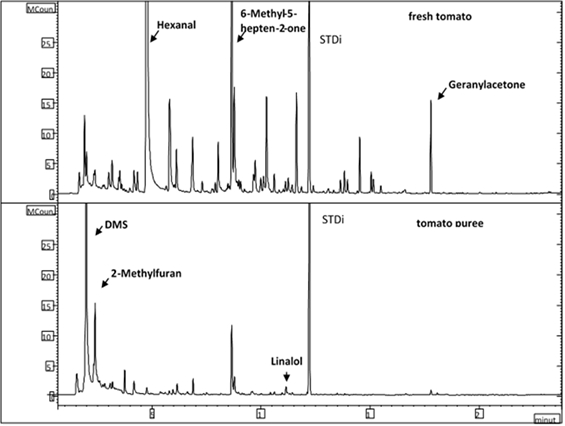

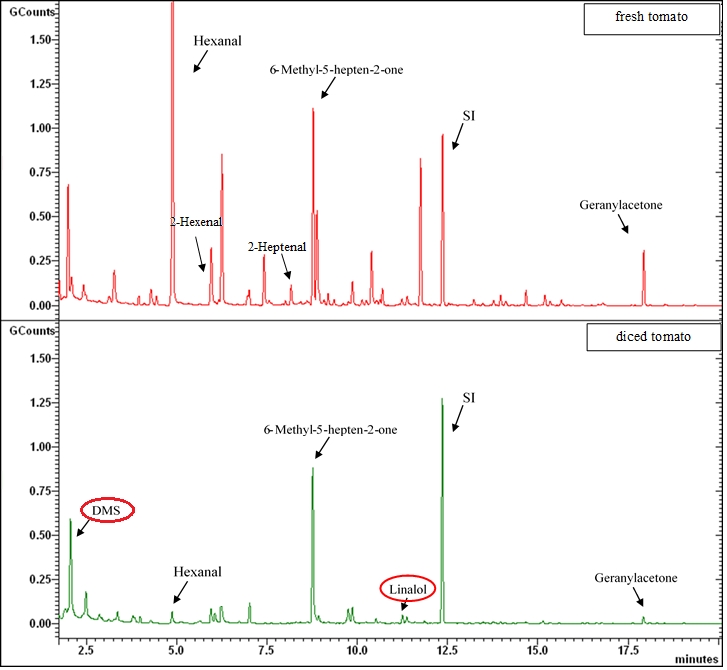

The characteristic flavor of tomato comes from a complex interaction of non-volatile and volatile aroma compounds. The main tastes – sweet, sour, salty, bitter and umami – are perceived by certain regions of the tongue, while volatiles are perceived by the olfactory nerve endings of the nose. In particular, sugars, organic acids, salts and free amino acids are the major components responsible for tomato taste. In tomato fruit, more than 400 volatile aroma compounds have been detected, but surprisingly, some of the most abundant compounds were not found to be significant in defining tomato aroma intensity. However, about ten molecules were shown to play important roles in fresh tomato flavor: a combination of cis-3-hexenal, hexanal, 1-penten-3-one, 3-methylbutanal, trans-2-hexenal, 6-methyl-5-hepten-2-one, methyl salicylate, 2-isobutylthiazole, and β-ionone. Fig. 3 presents a comparison between the profiles of the volatile molecules of fresh tomato, tomato purée and diced tomato.

Fig 2. Comparison between the profiles of the volatile molecules of fresh tomato, tomato purée and diced tomato.

Natural bioactive compounds of tomato

Epidemiological studies have reported an inverse correlation between the consumption of tomatoes or tomato products and the incidence of some types of cancer and cardiovascular diseases. These protective effects for human health have been attributed to the presence of a very interesting complex of antioxidant compounds, such as lycopene (the most important agent responsible for the final red color of tomatoes), as well as vitamin C, polyphenolic and free amino acids. Phenolic compounds in tomatoes are mainly represented by flavonols (quercetin, rutin and kaempferol glycosilated derivatives) and flavanones (naringenin glycosilated derivatives). In tomatoes, free amino acids account for about 2% to 2.5% of the dry matter. Among these, glutamic, γ-aminobutyric (GABA), aspartic acids and glutamine make up about 80% of the total amino acidic fresh pattern. The composition of amino acids depends on the ripening stage, type of cultivar, soil and climate conditions, truss positions and fertilization practices. Amino acids are considered important food compounds, having not only nutritive value, but also providing several health benefits such as anti-mutagenicity as well as a capacity to help reduce blood-sugar levels and prevent coronary heart disease. Amino acids affect the taste properties of tomato and tomato products. The amount of alanine, threonine and glutamine can influence the sweet taste. Furthermore, the umami/sour taste is affected by the concentration levels of glutamic and aspartic acid that are clearly responsible for the umami taste. Additionally, amounts of phenylalanine, leucine and histidine can affect the bitter taste of tomato. All these complex relationships and ratios in the raw materials and, above all, during and after processing operations, are among the main topics of the latest SSICA research and development studies. (Fig. 3)

Fig 3. Comparison between free amino acids of fresh tomato, tomato puree and diced tomato profile

SSICA R&D Topics

The growing context of commercial competitiveness and international economic crisis affecting the canning sector has led the Italian processing industry to strengthen activities that can increase production efficiency and develop added-value products. The main strands of tomato experimentation have been research in the field of genetic improvement, varietal research in order to obtain more vigorous and productive plants with specific characteristics, more resistances to different pathologies, the introduction of innovative processing technologies able to preserve all the aforementioned quality features, and the recovery of processing by-products that until now have been considered as waste.

In this context, the SSICA Research Foundation (Experimental Station for the Food Preserving Industry) has in recent years focused much of its research on the study of bioactive substances naturally present in the raw material and in the industrial by-products of tomato, as well as on their evolution during the different phases of industrial processing operations. As an example, it is useful to observe how “usual” varietal studies have been organized annually, and then compare new tomato cultivars in order to select the better ones for their characteristics and their suitability for specific industrial product categories (diced tomatoes and tomato puree).

The study has been divided into several steps, including:

- Selection of the cultivars coming from the interregional list;

- Cultivation in experimental fields;

- Processing of raw materials into industrial tomato products;

- Chemical-physical, qualitative and nutritional characterization of both fresh tomatoes and processed products;

- Evaluation of the way specific industrial processes affect distinct varieties, taking account of analytical and sensory results.

In particular, field trials have been conducted every year since 1990 in the Regional Experimental Fields (by A.A.S.Stuard), always in strict collaboration with the O.I. Pomodoro Nord Italia (Interbranch Organization for Northern Italy Tomato Supply Chain) with the aim of introducing new updated varieties for the requirements of tomato processors in the northern region.

In particular, field trials have been conducted every year since 1990 in the Regional Experimental Fields (by A.A.S.Stuard), always in strict collaboration with the O.I. Pomodoro Nord Italia (Interbranch Organization for Northern Italy Tomato Supply Chain) with the aim of introducing new updated varieties for the requirements of tomato processors in the northern region.Analytical and technological laboratories that report back to the Tomato Department of SSICA have been put in charge of the general assessment of the quality of raw materials, of the evaluation of nutritional quality, and of the processing into specific products (diced or purée) performed with the exclusive use of pilot plants on a semi-industrial scale. It should be highlighted that until 2008, the project only involved the evaluation and processing of diced tomato, whereas from 2009, it included tomato purée in order to expand the range of products being studied. As the experimentation progressed over the years, the studies focused on substances known for their nutraceutical value. Lycopene analysis has been introduced since 2010, to assess the changes associated with industrial processing. This is due to the growing interest of consumers in foods that are naturally rich in antioxidant compounds. Starting in 2011, sensory analysis was introduced for processed products, both for diced tomatoes and purée, in order to assess color, smell and taste. From 2014-2015, further qualitative parameters were introduced: polyphenols, amino acids and ascorbic acid as taste precursors, as well as volatile components for flavor characterization.

Each year, the tested cultivars are differentiated into two distinct transplant periods: early and late varieties grown in two separate fields in the region of Emilia-Romagna (by the Stuard Experimental Agricultural Company).

Varietal comparison tests have been carried out over the last few years:

- First level tests: this level examines new cultivar suggestions from seed companies, using control varieties (witnesses). The best cultivars in terms of bio-agronomic and qualitative parameters are evaluated by experts in the field, and then put through to second-level tests, which involve experimentation during the following harvest season.

- Second-level tests: they provide the opportunity for comparing the best varieties of recent years with those that get the best results from the first-level tests. The outcomes of these tests determine the insertions in the regional lists of varietal orientation.

Some commercial tomato cultivars selected by a commission of experts from the interregional varietal list are grown in triplicated randomized blocks in experimental fields (by A.A.S.Stuard located in Emilia-Romagna). These cultivars are harvested at ripening stage (nearly 85% of maturity) and promptly delivered to SSICA for the implementation of the protocol described above. A representative sample of the fresh tomato grown is subjected to agronomic evaluation, in order to identify major defects (foreign bodies, green and rotten fruit) or minor ones (crushed or split fruit, leaves, sunburn, superficial lesions of mechanical origin, etc.). Then, the main chemical-physical and nutritional characteristics of the raw materials are analyzed and, in addition to this routine analysis, the volatile profile and the nutraceutical components are analyzed.

A total of 8 to 12 varieties are usually tested each year by the researchers (half being early-transplanted varieties and half being late-transplanted varieties).

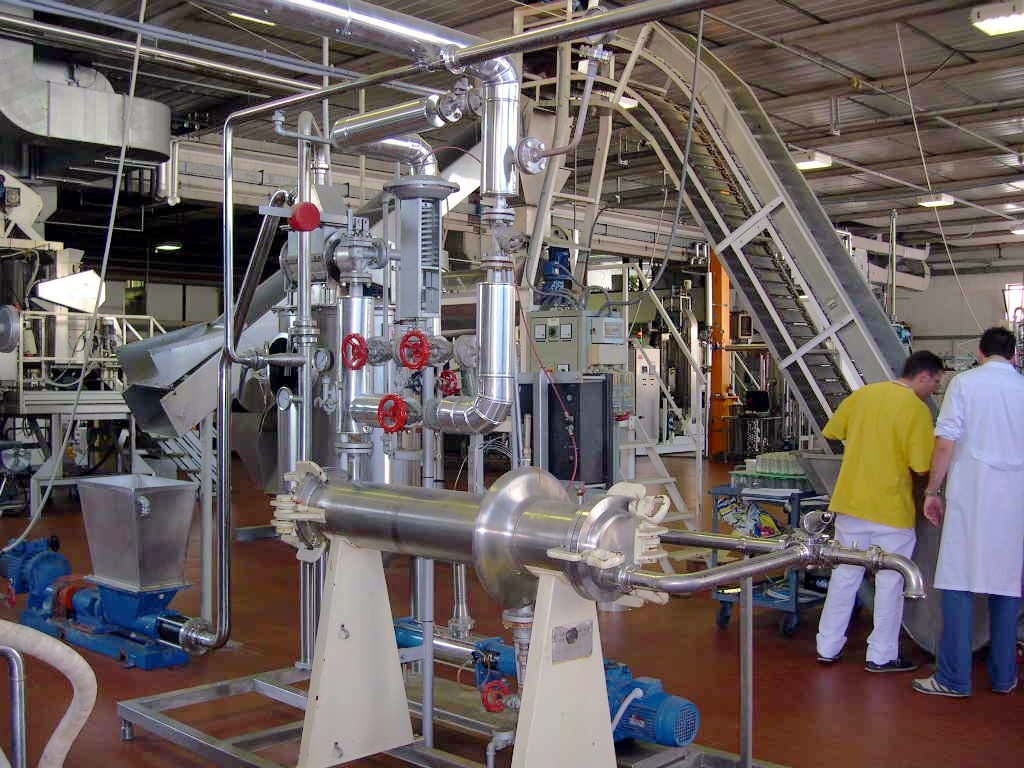

After a first quality-evaluation, a representative amount (250 kg) of each variety being tested is industrially processed into a final tomato product (puree or diced tomatoes) using the SSICA technological department’s pilot plant at semi-industrial scale.

Finally, all the processed products obtained are analyzed in triplicate, after a period of 30 days of shelf life (quarantine after processing equilibrium) measuring the same molecules as described above.

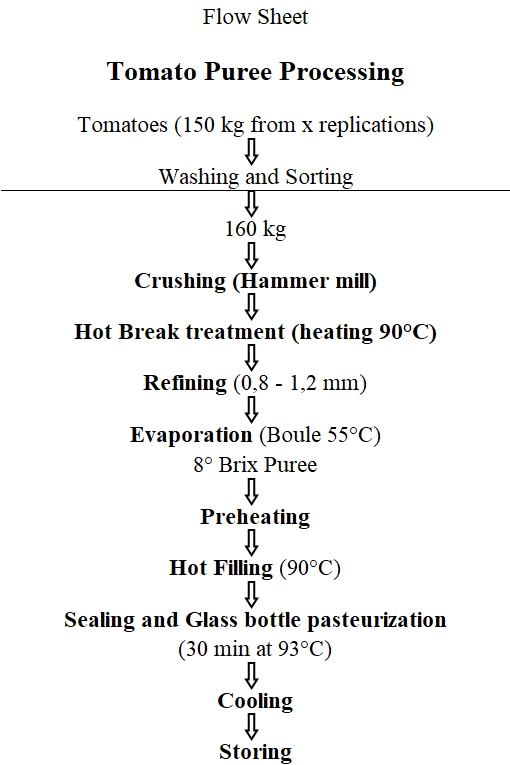

Fig 4. Processing Flow Chart of Tomato Purée (SSICA semi-industrial scale pilot plant)

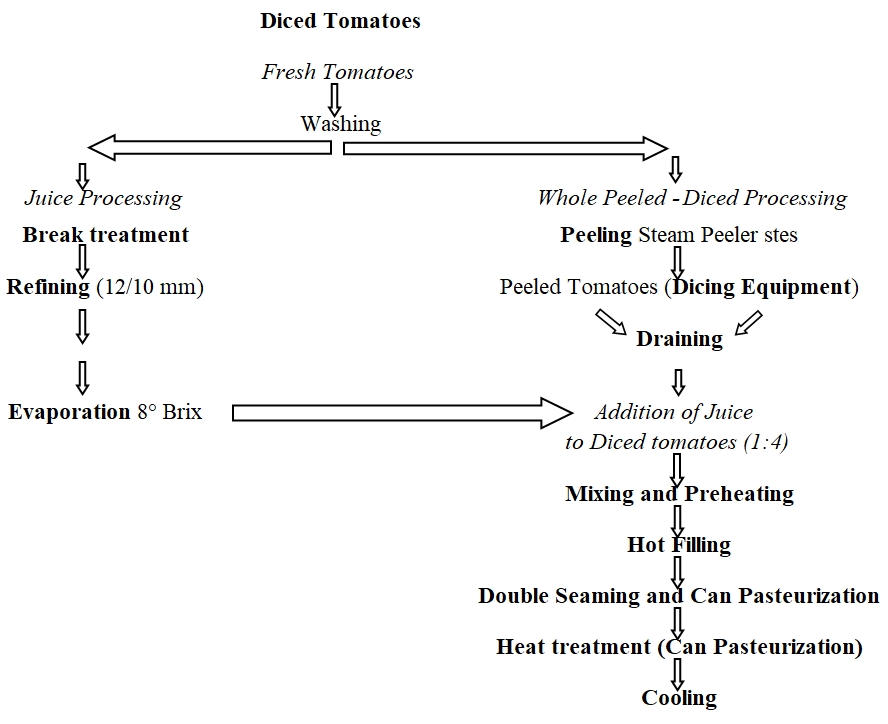

Fig 5. Processing Flow Chart of Diced Tomatoes (SSICA semi-industrial scale pilot plant)

Tomatoes were harvested and delivered by A.A.S.Stuard to SSICA labs (within 24 hours), where they were immediately evaluated according to fixed agronomic quality parameters and criteria used by the IO of the Northern Italy Tomato District. Industrial processing was performed by the SSICA technological department in their semi-industrial pilot plants. The purée processing protocol in use was: 200 kg of fresh selected fruit are washed, sorted, hot-break treated (T=90±2°C), refined (through a sieve with 12/10 mm Ø holes), evaporated through a conventional vacuum evaporator (Rotofilm at 55°C) until they reach 8.0°Brix, and then hot-filled (90°C) into a glass bottle after pre-heating. The bottles are finally hermetically closed and thermally pasteurized (25 min at 96°C), before being cooled and stored at room temperature. (Fig. 5)

Diced tomatoes are obtained after washing, sorting, thermo-physical peeling, sorting of whole-peeled tomatoes and dicing (11x11 mm). Then tomato puree at 7.5°Brix is added to the diced tomato at a 1 to 4 ratio, and the product obtained is pre-heated (96°C) in a mixing system and hot-filled in cans, which are subsequently seamed and pasteurized (25 min at 99°C) before cooling. (Fig. 6)

Conclusions

The food industry is facing some tough challenges linked to global social evolution (ever-increasing urban population, decrease in consumption of homemade processed food, constant evolution in cooking towards middle-class tendencies, diets for an increasingly ageing society, awareness of health benefits of bioactive molecule-rich foods (functional foods)). Moreover, international nutritional guidelines (WHO, USDA, EUFIC, etc.) recommend eating more fruit and vegetables, fiber, vitamins, potassium, etc., and they now recommend eating less food that is rich in calories, saturated fats and sodium.

The food industry is facing some tough challenges linked to global social evolution (ever-increasing urban population, decrease in consumption of homemade processed food, constant evolution in cooking towards middle-class tendencies, diets for an increasingly ageing society, awareness of health benefits of bioactive molecule-rich foods (functional foods)). Moreover, international nutritional guidelines (WHO, USDA, EUFIC, etc.) recommend eating more fruit and vegetables, fiber, vitamins, potassium, etc., and they now recommend eating less food that is rich in calories, saturated fats and sodium.Tomato is a major component in what is called the “Mediterranean Diet”, often associated with a healthier lifestyle. Owing to the presence of a set of lipophilic and hydrophilic biomolecules, tomato products are rich sources of natural bioactive compounds such as carotenoids (lycopene, β-carotene, lutein, phytoene, etc.), vitamin C and A, phenolic molecules such as flavonoids and phenolic acids. They are also important sources of potassium, folates, fiber and unsaturated fatty acids and enzymes. For all these important nutritional characteristics, tomato products are considered to be very important, worldwide, in terms of public health and wellbeing. With increasing interest and awareness of the health benefits of natural tomato bioactive compounds (mainly lycopene), the tomato industry has focused more and more attention on all the aspects and relationships related to the nutritional quality and health benefits of processed tomato-based foods.

In recent years, specific research has been focused by SSICA on topics related to the needs of consumers and the requests for attractiveness of Italian processed tomato products that are “healthy, tasty and yummy”. This has led to:

- The formulation of food proposals with nutritional characteristics that are suitable for enhancing the competitiveness and skills of the horticultural value chain;

- Genetic selection for increased productivity and plant quality according to new market requirements and the capacity to adapt to climate change;

- The recovery, characterization and enhancement of biodiversity, in order to foster an increase in production diversification for the “Made in Italy” products market;

- The development of innovative systems and/or technologies aimed at sustainable management in terms of water, energy and management of plant-health issues (circular economy);

- The development of new functional food products and their formulation in order to prevent and reduce the concentration of “dismetabolisms” and to maintain wellbeing (there is a close relationship between diet, health and human wellbeing) with particular attention to the needs of people in the younger and older age-brackets (sanitary and nutritional security, sustainability and quality of food systems);

- The development of environmentally sustainable processing technologies, respectful of the environment and attentive to the quality of the products (mild technologies).

As always, the SSICA must fulfil its institutional duties in order to carry out innovative studies that continue to enhance knowledge of all aspects of the processing chain (from farm to fork) in order to meet the future requirements of industrial operators and deal with changes of the markets.

Source: SSICA

Parma, 26 March 2019

In particular, field trials have been conducted every year since 1990 in the Regional Experimental Fields (by A.A.S.Stuard), always in strict collaboration with the O.I. Pomodoro Nord Italia (Interbranch Organization for Northern Italy Tomato Supply Chain) with the aim of introducing new updated varieties for the requirements of tomato processors in the northern region.

In particular, field trials have been conducted every year since 1990 in the Regional Experimental Fields (by A.A.S.Stuard), always in strict collaboration with the O.I. Pomodoro Nord Italia (Interbranch Organization for Northern Italy Tomato Supply Chain) with the aim of introducing new updated varieties for the requirements of tomato processors in the northern region.

The food industry is facing some tough challenges linked to global social evolution (ever-increasing urban population, decrease in consumption of homemade processed food, constant evolution in cooking towards middle-class tendencies, diets for an increasingly ageing society, awareness of health benefits of bioactive molecule-rich foods (functional foods)). Moreover, international nutritional guidelines (WHO, USDA, EUFIC, etc.) recommend eating more fruit and vegetables, fiber, vitamins, potassium, etc., and they now recommend eating less food that is rich in calories, saturated fats and sodium.

The food industry is facing some tough challenges linked to global social evolution (ever-increasing urban population, decrease in consumption of homemade processed food, constant evolution in cooking towards middle-class tendencies, diets for an increasingly ageing society, awareness of health benefits of bioactive molecule-rich foods (functional foods)). Moreover, international nutritional guidelines (WHO, USDA, EUFIC, etc.) recommend eating more fruit and vegetables, fiber, vitamins, potassium, etc., and they now recommend eating less food that is rich in calories, saturated fats and sodium.