Adapting the cultivation of processing tomatoes to climate change

Adapting the cultivation of processing tomatoes to climate change is not an easy task for growers: industry requirements, notably in terms of color, but also of Brix, are increasingly tight, and the development of such crops is a long and drawn-out process. Despite this, Portuguese agronomists are permanently working to further improve the acknowledged high quality standards of the country's industry.

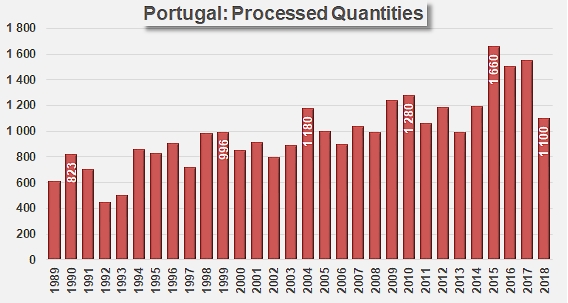

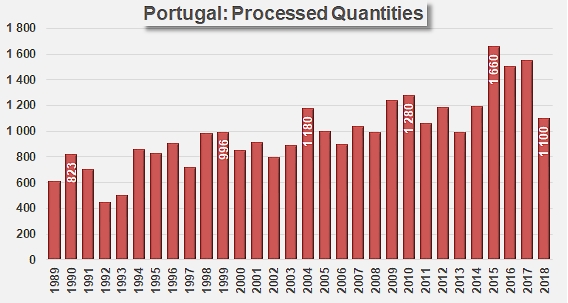

This year, the surfaces dedicated to processing tomatoes have dropped sharply in Portugal, like in several other European countries (see our article published on 2 July and the bimonthly season's updates). Furthermore, the development of the crops was delayed "because of the persistent rain that fell in March and April, which did not allow planting to be carried out according to plan in terms of schedule and extent, and plant development was affected by cold weather," explained the growers. Some growers did not finish planting operations until the very first days of June, and these operations we only possible over a much shortened period of time compared to normal.

Are profit margins too narrow?

However, despite these difficult conditions, research is still being carried out to facilitate and guarantee the high quality of the product obtained – raw tomato for processing. To quote the growers themselves: "the main requirement of processors is color, which is valued above 2.10", but the "ideal color value is between 2.40 and 2.50." The soluble solids content (in °Brix) is also an essential criterion, with a target of 5.5, and lycopene content is increasingly sought-after. The main issue for growers is not so much the way their production is evaluated by the processing industry according to color or Brix, but the risk of penalties that they run if color or Brix values are too low, to the point of having their shipments rejected if these values do not reach a certain level.

As growers explain, it is difficult to reconcile these different requirements, when the "high color varieties are low in Brix and vice versa. [...] We didn't have a lot of problems last year, but we only achieved an average color of 2.10 because of infestations of mites and white-fly in a number of plots, which do not let plants go all the way to the end of their production cycle. [...] Growing tomatoes that only reach the minimal standards expected by processors is not profitable, and even with average quality values, it's touch and go." The quality expected by the processing industry requires a high investment in the agricultural process, estimated at approximately EUR 7 500 per hectare by Portuguese Producers' Organizations in 2018, a cost that POs say is constantly increasing while the price of tomatoes has tended to decrease.

This pressure is aggravated by the heavy demands of the industry in terms of quality, and growers lament the fact that the number of active substances allowed for dealing with plant-health issues has been dwindling while their cost has been increasing. "Because the profit margins are too narrow, some growers decide to run the risk of delaying treatments by two or three days, as the price can amount to approximately EUR 90, the equivalent of a tonne of tomatoes."

Adjusting inputs to the most basic requirements of the plant

In order to manage the crop as precisely as possible, some growers have equipped their fields with humidity sensors and have been working with third-party contractors to carry out analyses every fortnight or, if circumstances require it, every week or even every day.

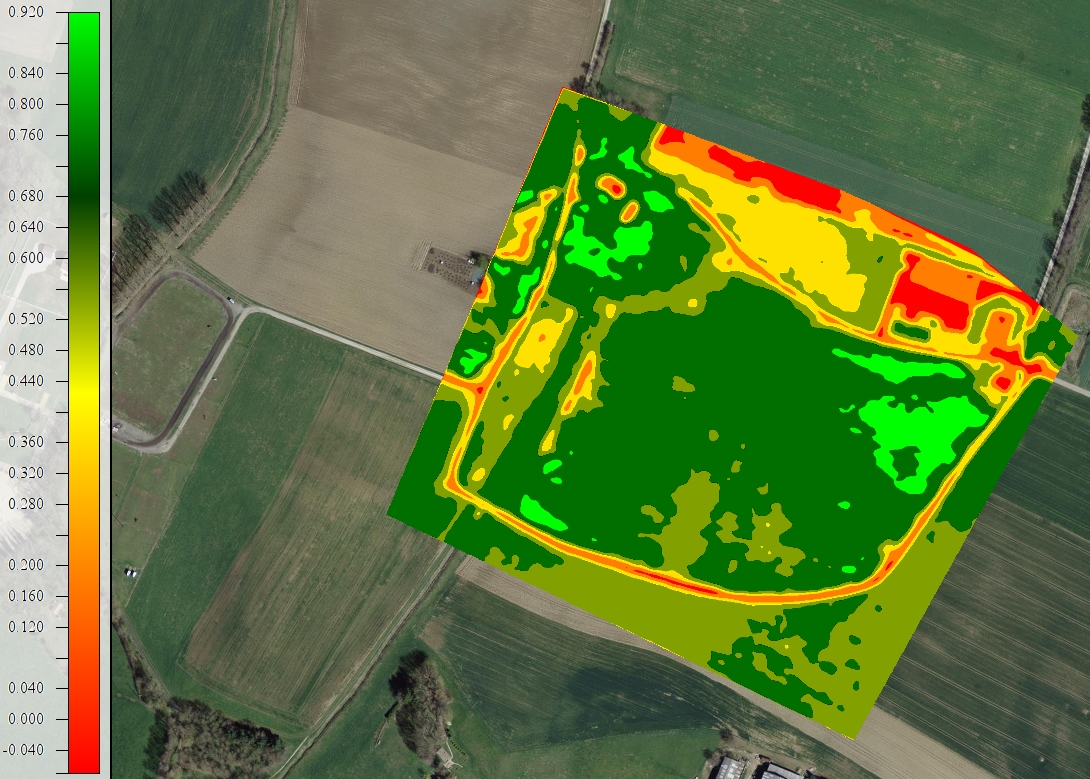

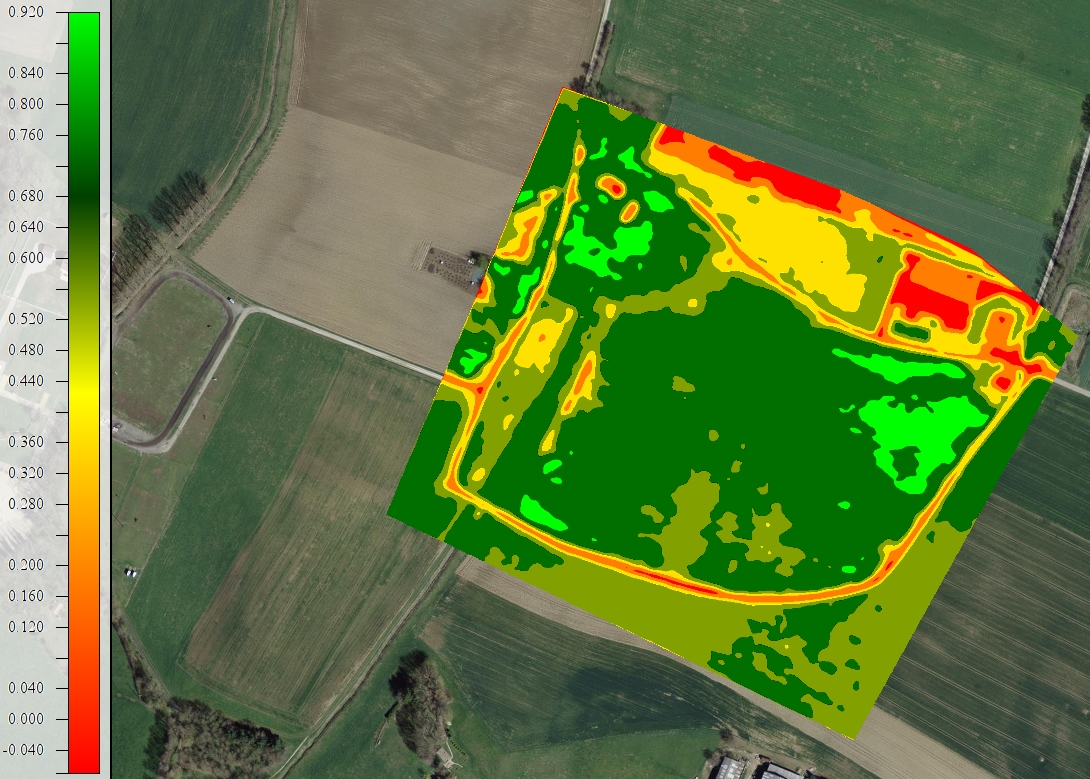

A number of them also make use of information obtained from NDVI maps (Normalized Difference Vegetation Index) that allow them to identify spatial or temporal variability in the health of the crops. POs also carry out diverse tests in a laboratory, in the context of their Global GAP certification.

A number of them also make use of information obtained from NDVI maps (Normalized Difference Vegetation Index) that allow them to identify spatial or temporal variability in the health of the crops. POs also carry out diverse tests in a laboratory, in the context of their Global GAP certification.

As for crop amendments, growers explain that they use solid fertilizers in the early stages of development, which are then replaced by fertigation throughout development and right up until the end of the harvest. On this point, like for procedures against insect pests and weeds, the number of treatments and the doses used vary from year to year and depend on the needs of the crop, on the nature of the soil, on health issues, etc.

Growers who cultivate their own land are constantly looking for alternative crops that can be used in rotation with processing tomatoes. This approach is supported by POs and has led to the development of crops like peanuts, sunflower, potatoes and sweet potatoes. For similar reasons, a number of growers decided this year to leave some of their fields fallow. "We are convinced that this will work. In a number of fields, we are hoping that ryegrass and plants of the legume family will help to fight against the development of fungi in the soil, thus facilitating better conditions for crops the following year and reducing pesticide costs." For growers who are cultivating leased land, "the difficulty is to find available surfaces insofar as the best fields are already taken up by other crops."

2018: POs and processors agree on a reduction of planted surfaces

Mid-September, the INE (Portugal's national institute of statistics) confirmed forecasts announcing a drop of approximately 26% in the surfaces planted with processing tomatoes, which have fallen from 19 600 hectares in 2017 to a total of 14 400 hectares this year, which is the lowest they have been since 2013.

According to the INE, "this decrease is mostly the consequence of the difficulties encountered during last year's season in the area of plant health issues, with major infestations of whitefly and mites", with the result that a large number of growers have been put off this crop and "those who remain active in this sector have been led to reduce planted surfaces."

On this point, Gonçalo Escudeiro, the director of Torriba – a PO whose production is mainly grown for the Kagome Group (HIT (Italagro and FIT)) – pointed out that this drop in processed volumes "is a necessity, with processing companies facing the issue of surplus stocks of tomato paste after two big seasons in 2014 and 2015, and prices that have dropped sharply" for a product that remains "a basic commodity in a very globalized market." Before contracts were signed, meetings were held between processing operators and about fifteen POs in order to "determine a common strategy for improving value within the industry [...] and adapting the offer to the market situation in a context of surplus inventories."

These meetings also provided "the opportunity to talk through plant-health issues and the lack of active inputs available to fight against a number of parasites that affected crops in 2017" as well as presenting a request to the DGAV (Direcção-Geral de Alimentação e Veterinária) asking for exceptional authorizations regarding alternative active inputs that could overcome resistances in pests.

For Gonçalo Escudeiro, "the Portuguese industry must develop its own strategy that will allow it to defend the quality of its products, which is possible thanks to the proximity of the Atlantic Ocean. [...] We must therefore focus on these high quality standards and not on mass production, and neither must we base our sales simply on an approach linked to pricing."

For the Torriba PO, processing tomatoes account for approximately 50% of their operations. The PO's director has underlined the need to develop better hazard management, which "increases with growing climate instability." Gonçalo Escudeiro added that "with such narrow profit margins, there is no elbow room for taking risks." In this respect, "the state must support us by investing in efficient schemes to help manage crisis situations, including the key element of harvest insurance programs. [...] This point has been progressing: just five years ago, only about 5% of tomato growers were insured, whereas about 80% are insured today. But some situations remain excluded from the usual risk coverage, like the persistent rains that we had in March, and those do indeed require heavier intervention from the state."

A number of industry leaders are now underlining the need for yield-insurance, with the importance of shared insurance policies and premiums for agricultural activities.

Source : vidarural.pt

A number of them also make use of information obtained from NDVI maps (Normalized Difference Vegetation Index) that allow them to identify spatial or temporal variability in the health of the crops. POs also carry out diverse tests in a laboratory, in the context of their Global GAP certification.

A number of them also make use of information obtained from NDVI maps (Normalized Difference Vegetation Index) that allow them to identify spatial or temporal variability in the health of the crops. POs also carry out diverse tests in a laboratory, in the context of their Global GAP certification.