Interview of David Page, Research Fellow with the INRA (SQPOV Unit) (part 2)

Using infrared: from reception to the finished product

Tomato News: Given that infrared can supply precise and reliable measurements – at factory reception and within a few seconds – of soluble solids levels, of Brix, of the levels and state of pectins, of titratable acidity, can this approach form the basis for an intelligent interaction between science and industry?

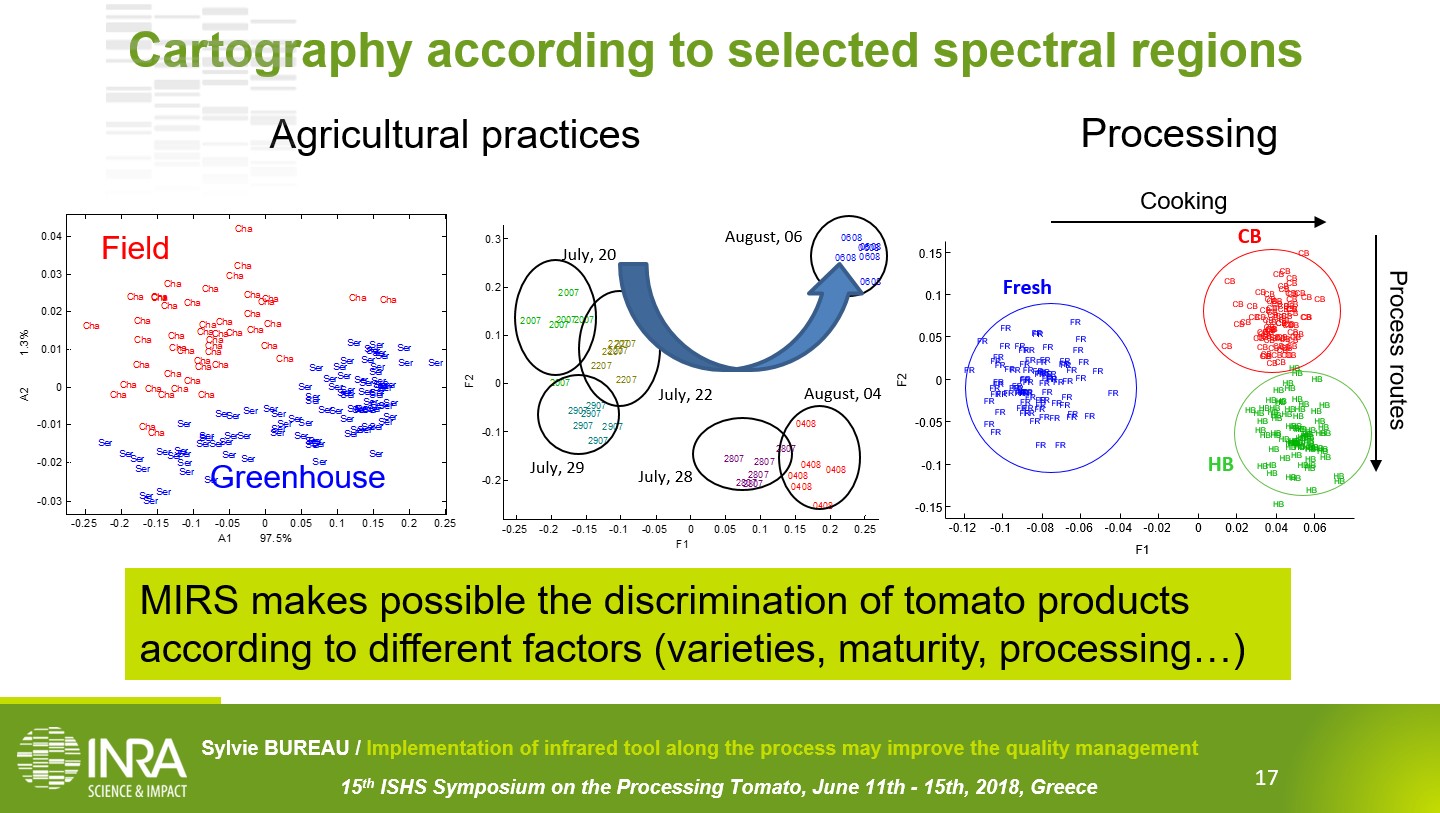

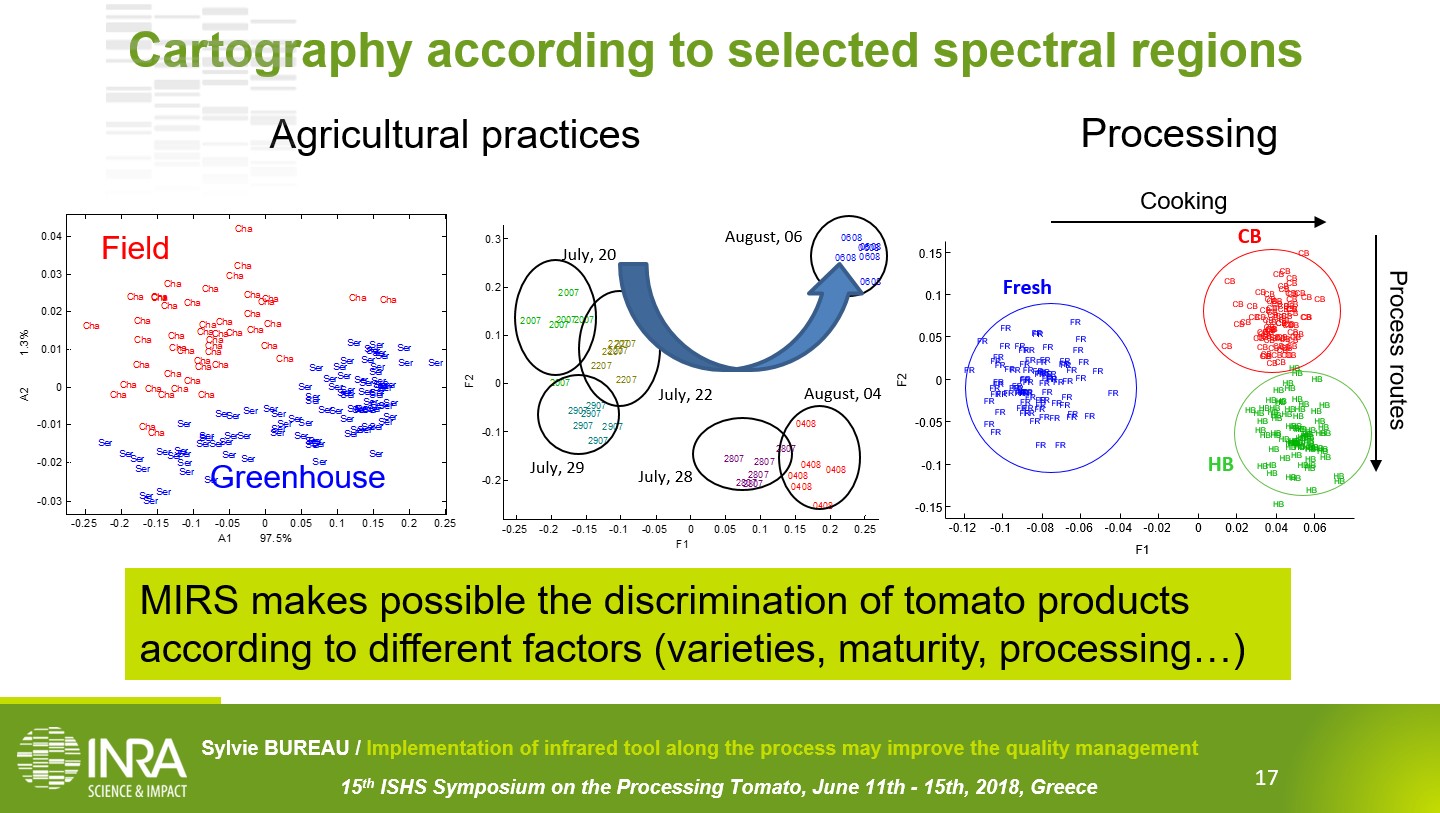

David Page: "The objective of this approach is to correlate the infrared signatures that are determined at factory reception – the characteristics of the raw materials – with those of the finished products. Responding to this question would be an answer to a complex logistical problem for which most industry operators tolerate a degree of approximation. But models are being set up, based on factory sampling, that are not yet sufficiently robust to be implemented at an industrial scale, but which have proven that infrared methods give reliable results that are completely compatible in practical terms with "machine time" and with in-line processing. In other words, infrared could supply a diagnosis in real time of the advancement of the process and the state of the product as it travels through the system, which is information that operators do not currently have. Acquiring the signatures in-line could also be combined with what we know of the ulterior phenomena affecting the evolution of products after final conditioning, during storage."

TN: Couldn't implementing infrared technology that is currently available in the pharmaceutical industry be exported to the food industry, for processing tomatoes, in order to supply in-line infrared measurements like those that have long been used to carry out in-line measurements of temperature or Brix?

DP: "Fiber-optics, laser technology, distant capture of signals, remote measurements, duplications, radio waves, wifi, smart phone applications,... there are many effective means of facilitating the acquisition of spectral or physical data and optimizing their use in processing, and this can increasingly be carried out independently from the conditions surrounding the measurements, which makes them increasingly powerful and accurate. With modern tools to acquire spectra, processors can replace the currently empirical measurements of Brix levels by a diagnosis of the level of real soluble solids during the evaporation phases, and will soon be able to integrate this infrared data into the control of equipment. More generally, processors can easily acquire immediate and direct knowledge of their raw material and of the way it behaves during the phases of the process, and they will soon be able to predict a number of characteristics that can help evaluate the quality of the product immediately after conditioning. Companies that invest in this area will be able to progress hugely in their knowledge of raw materials and the fine-tuning of their operations. Other industries like the wheat sector have already largely integrated this technology.

By progressing in the definition of products, of their precise characteristics and of their technical qualities, thanks to a vocabulary that is shared by growers as well as processors and their industrial clients, infrared could provide a real bonus in terms of equipment control, helping to reduce the proportion of non-standard products and thereby saving money. In the future, it will no longer be necessary to just deliver a batch of triple-concentrated paste to a manufacturer of prepared dishes, but it will be possible to supply an appropriate volume of technically sophisticated tomato product designed for manufacturing a covering sauce for ravioli. Consumers and users of the future will be more demanding in terms of quality: a number of industrial operators have already understood this, and are standing out within the industry by complying with these demands. It is going to become necessary to be more effective in dealing with these issues in order to remain competitive in the broader field of competition..."

Early indicators of end-product quality

TN: For several years, the INRA has been collaborating with the SONITO and the CTCPA on a project to provide results applicable to the upstream section of the tomato industry, for which the analysis of infrared spectra is considered particularly useful, allowing operators to develop cultivation methods that comply as closely as possible with the technical expectations of the industry...

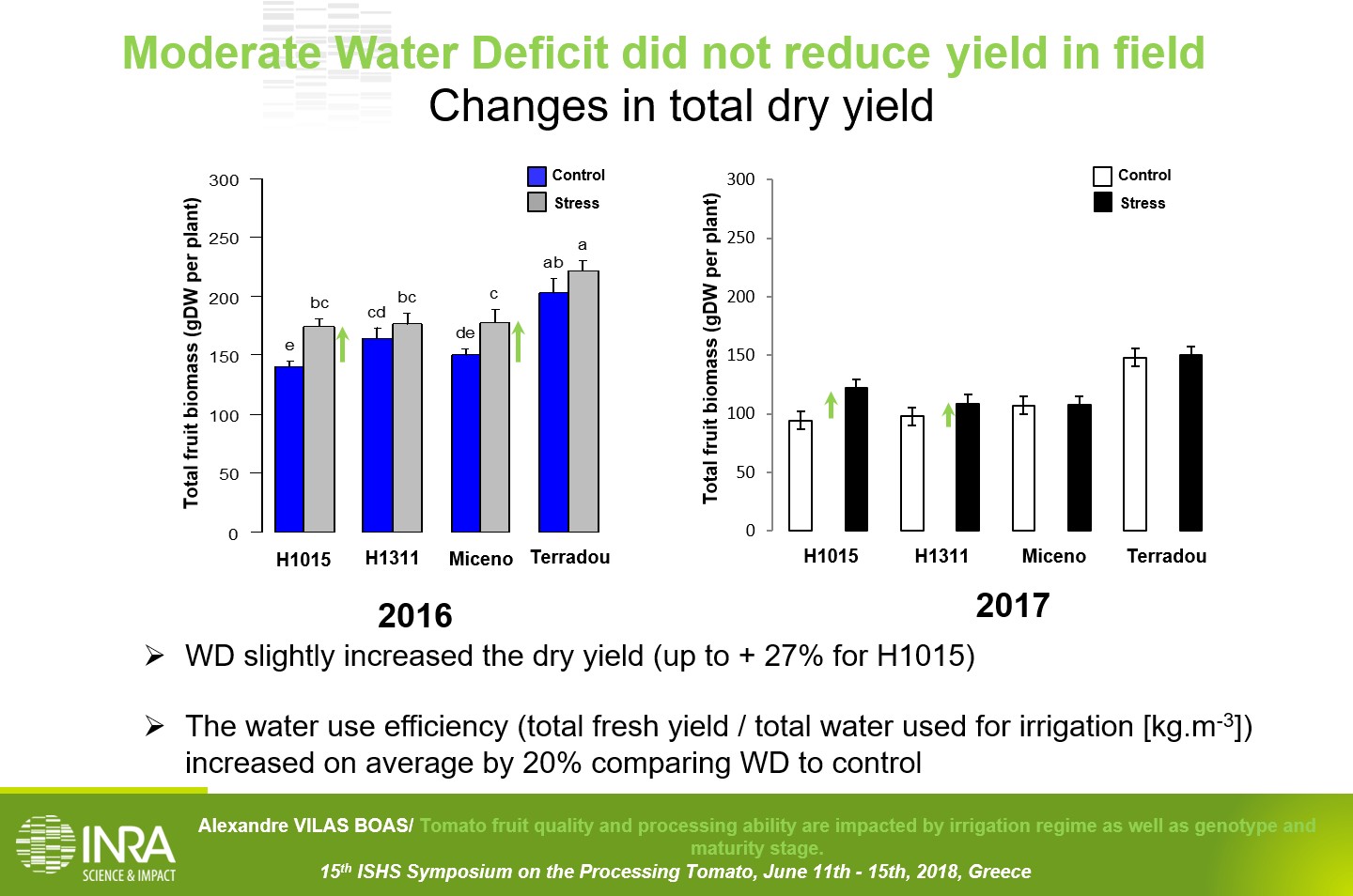

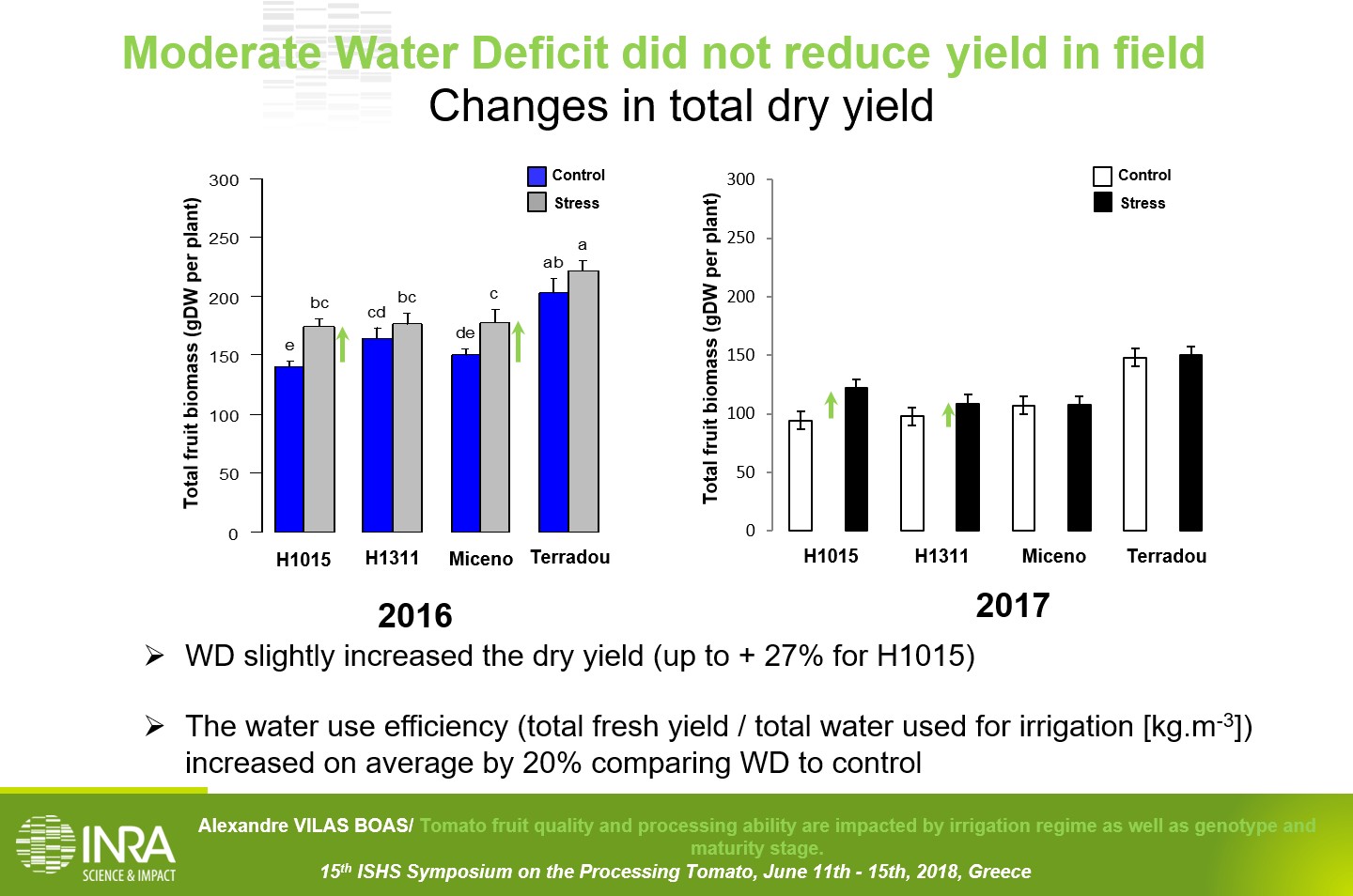

DP: "Everything that can be said of factory reception or ongoing processing procedures is also true for the upstream parts of the industry. The thesis of Alexandre Vilas Boas ("Tomato fruit quality and processing ability are impacted by irrigation regime as well as genotype and maturity stage") clearly shows that it has been possible, over two successive years, to strongly reduce the water inputs during cultivation without losing out on yields. A water input of only 50% of the evapotranspiration (ETP) between the blossom stage and the harvest (whereas current agricultural practice in France tends to provide more than 100% of the ETP) does not affect yield, as the soluble solids content of the fruit was slightly higher for two of the four varieties tested, and the fruit complied with the quality expected by processors. There was no biochemical difference observed between products made from crops with limited irrigation and those made from control crops."

TN: Economies in terms of irrigation water, transport, energy used in the factories for concentration operations, and reductions of the carbon footprint... These are all highly positive prospects. However, the commercial relationship between growers and processors is based on the volume of tomatoes that get delivered, adjusted to take account of quality criteria that include a measurement of soluble solids; today's growers do not sell dry weight...

DP: "That is because the industry does not have the tools – or did not have them until recently – to evaluate dry weight at the factory gate, in a way that is fast and reliable. Today, processors measure the Brix value and count on the Brix-soluble solids-viscosity link. In this context, growers sell a certain weight of raw fruit, and attempt to obtain good results in terms of Brix, which may result in them receiving a quality premium. Seed companies have followed the pattern and offer high Brix tomatoes, but this kind of selection has often been achieved at the expense of viscosity, as these two qualities seem to be relatively antagonistic, and some high Brix varieties have lost their capacity to produce high viscosity purées. This feature could be the result of competition for the carbon allocation absorbed by the plant and used for soluble solids and insoluble solids or, in other words, competition between Brix and viscosity. These phenomena can be described by the eco-physiological models that determine the way that the fruit fills out. Other production regions like California have not chosen to reward Brix content, but, on the other hand, have achieved a sufficient size to impose selection criteria on quality. Using an empirical approach, they have determined different categories for their varieties (thick, thin, intermediate…), but little is actually known about the cellular and biochemical mechanisms that determine this classification. In summary, what is needed is for industry to be convinced that it must shift its payment system for agricultural raw materials towards criteria that are more relevant to quality, and in particular taking greater account of the real dry weight delivered, rather than just Brix."

TN: Should dry weight be considered as the new absolute unit? The day can't be far off when it will be possible to place a battery of infrared sensors in the grading stations at factory reception...

DP: "Infrared sensors have shown their worth in laboratory settings, notably for controlling quality in a number of other industrial sectors (pharmaceuticals, but also wheat and the protein content of seed pulses), and they are ready to be installed in grading machines as soon as the profession decides to focus on this issue. But above all, the industry as a whole remains to be convinced of the legitimacy and advantages to be found in adopting a different payment model, but it needs to be done quickly: the current evolution of the climate context is very soon going to lead to major constraints, not only from an economic point of view, but also from the environmental or social points of view... This is already the case in California, where for several years they have been facing recurrent problems of water availability. It is slightly less of an issue in the countries of the northern Mediterranean rim, but for countries of the south Mediterranean, it is a major concern. We need to concentrate on an intelligent relationship between growers and processors, and set up the necessary tools and the essential support systems to encourage a dialogue between the different parties, in order to replace the "quantity" discussion with another discussion based on "quality" or "technical features". Growers should pay more attention to this aspect of their business, and more specifically to potential improvements in the way they proceed with cultivation. Understanding how to obtain a "dry weight that is optimized" for growers and processors will be one of the decisive advantages for tomorrow's cultivation sector, when the constraints imposed by laws on water usage will become even more of an issue.

Genetic resources have already anticipated this goal and been explored with this in mind, like the Israeli researchers who selected lines that require very little water and yet record good yields in experimental trials. But these are not the only available genetic resources, and there are others that are particularly interesting in the field of experimental genetic resources. Our industry is fortunate that tomatoes have been the model plant for genetics research and eco-physiologists, and they were the first plants producing fleshy fruit whose genome was entirely sequenced, meaning that it was the first fruit for which a good number of genes were identified and characterized for their functionalities, featuring a large quantity of available markers on their genomic profile, allowing efficient and accurate selection. This means that in order to solve tomorrow's problems and reach tomorrow's objectives, scientists already have genetic knowledge that has not really been put to optimal use by the tomato industry in selecting the criteria suitable for processing. In particular, it would be advisable to determine more genetic markers linked to quality or to resistance in circumstances of low-level irrigation, so as to be able to take account of these criteria earlier in the selection process. There is still little control exerted on these criteria and they are not granted the same priority status as resistance genes against insect pests, whereas they are actually a prerequisite for varieties to be selected by operators. In this way, genetics could become a more efficient tool in selecting processing tomatoes that are adapted to requirements."

TN: Such research results are one of the hot topics for the tomato processing industry and regularly feature in publications and communications like those that were presented during the 15th ISHS Symposium on the processing tomato hosted in Greece in June 2018. Today, researchers from all over the world, and the multidisciplinary teams of the INRA in particular, have a big contribution to make to the industry.

DP: "At the same time, research needs closer relationships and collaborations with industry, because it is increasingly difficult to finance this kind of work, as public resources are dwindling and are being redirected towards higher priority issues, and because we need to have a better understanding of the reality of the processing industry. A lot of concrete results could become available if these interactions were set up and, for example, if the issues that are also being discussed by our Italian "neighbors" of the SSICA, or our Spanish neighbors of the CTEAX, who are highly knowledgeable on a number of topics of interest to the tomato processing industry, were to benefit from shared resources and jointly receive some answers."

Conclusion

"A lot of the resources currently dedicated to research by the INRA are invested in understanding and acquiring knowledge of products, and exploring issues that go well beyond the usual framework of chemistry, biochemistry or microbiology, involving aspects of physical sciences, working at both macro-metric and micro-metric levels on the size of particles, on the characterization of plasma... We are now able to provide very relevant diagnoses, so the main issue at the present time is to know how we, as researchers, can collaborate with our technical structures like the CTCPA or the French Sonito interbranch organization to make these tools and results completely operational and contribute to the emergence of a new vocabulary, a new way of characterizing and considering tomato products."

TN: We are talking about a common vocabulary that can be jointly used by growers, agricultural technicians, grading operators, processing operators, distributors, secondary users and consumers?

DP: "At the very least, a commercial vocabulary, and if I was an operator in this industry today, I would carefully consider the fact that final consumers are increasingly well-informed and are asking more and more relevant questions that are going to condition their food choices in a profound way... As researchers and industrial operators, if we can be at the forefront of this kind of concern, in order to answer these questions, we will have all the more opportunities to provide the right responses when they become key issues. This is how we should be thinking…"