Following the Conference…

Based on the presentation by Douglas Gilman during the Tomato News Conference held in Avignon, France, 16-17 May 2019

Among the many aspects of the industry that were mentioned during the Tomato News Conference (16 and 17 May 2019), the future of tomato processing operations was a thread that ran throughout all the discussions. In its different forms, with a number of original ideas, tomorrow's tomato industry was debated, described or re-imagined by several speakers, particularly in the context of the third session, dedicated to the topic, "Building the future: innovation and research in technology" moderated by AMITOM President Sónia Neves da Silva.

According to a recent report, today's consumers want products that are practical, natural, highly nutritious, free from additives, and functional. In order to meet these requirements, food processing companies are increasingly making use of non-thermal technologies. In addition to ohmic heating techniques, to which we will return in the coming weeks, and to the implementation of "infrared" technologies to which Tomato News dedicated a special report in the 2019 Yearbook, this session provided the opportunity to discover the advantages and opportunities of high-pressure processing, or HPP, thanks to a presentation by Douglas Gilman.

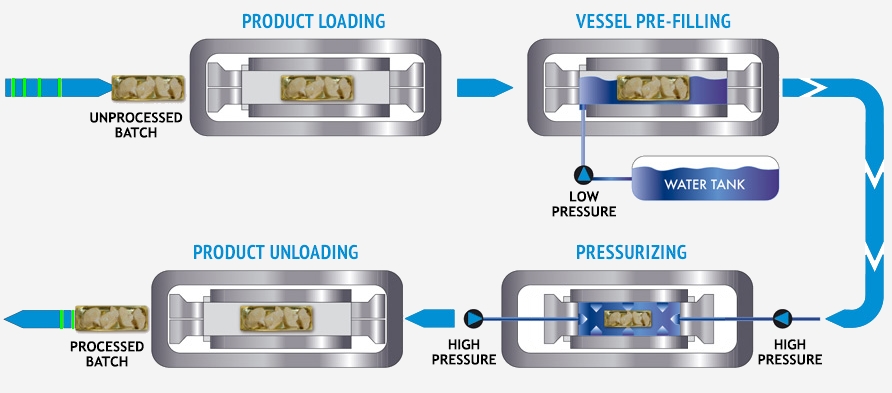

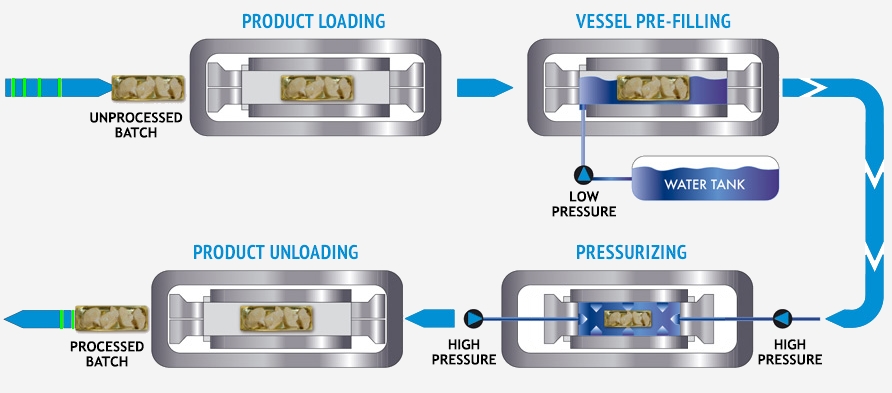

Operating diagram of a HPP unit

HPP technology, a USDA-approved process, is a cold pasteurization technique by which products, already sealed in their final package, are introduced into a vessel and subjected to a high level of isostatic pressure (300–600 MPa / 43 500-87 000 psi) transmitted by water. The effectiveness of the HPP process depends on the amount of pressure applied, vessel holding-time, temperature, product type, and targeted pathogens and spoilage organisms.

The natural pressure exerted by the water destroys possible pathogenic agents and any organisms that cause deterioration in the food product (bacteria, viruses, yeasts, molds, and parasites). Unlike heat-based technologies that can alter or destroy vitamins and affect the taste, high pressure offers a solution to processors who want to supply products that are fresher, healthier and safer.

The representative of the third generation of owner-managers of the GL Foods Group used examples (taken from processed products other than tomato) to show how, with easily transferable models, the implementation of "high pressure" processes had led to solid profitability by offering consumers products that are not cheap but are really innovative...

Speaking of technologies that have rarely, if ever, been used in the tomato processing industry despite the fact that they are particularly innovative and perfectly suited to consumer expectations, Douglas Gilman told the "success story" of a Portuguese family company founded 75 years ago, whose two product brands – Fresco for the US market and Sonatural for the rest of the world – have emerged into a difficult market, but have met with remarkable success in recent years. He insisted on the constant focus on innovation in the way the company is managed: “We’ve been all the time driven by innovation. Innovation is our present, it has made us live during the 75 past years and we think it will make us live for the next 75 years. Innovation for us is the most important thing, we think of innovation every day."

The company is involved in two different business operations linked to its two brands, depending on its different market segments, like sandwiches, snacks and salads. Closer to the processed tomato sector, GL Foods is also very active in the segment of cold pressed juices, a business that it launched in 2004 and for which GL Foods is currently the biggest European producer. The challenge during the launch of this business project consisted in forging an identity that was different from the Compal brand, the acknowledged leader in Portugal for the high quality pasteurized juice segment. The idea of making use of a new technology used in the United States, called HPP (high-pressure processing) began to grain ground. High-pressure technology is a process that does not involve heating, in which processing temperatures never exceed 5°C, the purpose of which is to inactivate the micro-organisms found in the product, without needing to use heat. The process prolongs the shelf-life of a product.

What lessons can be learned from this technology? Firstly, it is important to note that it is quite costly, and requires heavy investments. Secondly, in complete contradiction with the established practices of the tomato processing industry and more extensively with those used in the pasteurized juice sector, this is a discontinuous technology that requires "batch" processing (about 1 000 liters every 4 to 5 minutes). These two aspects are extremely important, and potentially limiting, though they have clearly not been an obstacle to GL Foods in its search for a clearly acknowledged identity:

“We saw we have to be different, and this technology replicates what we do at home with fresh produce, when we cold-press it in the same way as HPP, getting the same product with 90 days of shelf-life.” However, it is necessary to use only top-quality materials, and Mr. Gilman insisted on the fact that it is not conceivable to use low-grade materials in order to obtain a good quality end product with HPP.

Clean label: a core requirement of the market

One of the current trends that are growing at the moment in the field of consumption is the demand for "clean labels", in other words, packaging labels that guarantee the absence of additives that may be more or less controversial or undesirable. More than ever, consumers are paying attention to the quality of what they eat and drink, and they require detailed information that can reassure them about the ingredients that compose the products they buy and consume. Not only are consumers increasingly interested in fresh food and drink that is practical and less processed, but they are also willing to spend more in order to buy healthier products. Furthermore, modern consumers (particularly millennials) are paying attention to the production methods of their food before they buy a product.

In order to respond to this demand on the part of consumers and to their growing concerns regarding food safety and health issues linked to eating habits, processors and distributors are on the lookout for reliable and innovative methods to stabilize and preserve food products, among which is high-pressure processing, which can guarantee the best quality possible for the food. This approach is part of a double objective focusing on safety guarantees for consumers and protection of the brand image.

One of the main challenges that had to be overcome in launching this technology was its high cost, but paradoxically this aspect also had the positive consequence of motivating careful consideration for the sales price of products made with HPP technology, which had to be sold at 2 to 3 times the price of equivalent products obtained with normal pasteurization procedures. Specialists explain that the cost of HPP varies depending on the size of the production runs, fill efficiency of the product within the HPP vessel and process parameters. But these costs may be offset by other price reductions that HPP enables such as eliminating food additives. HPP also brings operational benefits such as lower energy usage as it only requires the use of water, which is recyclable and environmentally friendly.

"Give it a shot" won the Innovation award at the SIAL International Exhibition 2018

GL Foods was the first company to use this technology and to sell this type of product, though it sometimes required marketing methods similar to the battle between Don Quixote and the windmills... Competition from a Dutch competitor in the same sector of "such fantastic products as cold pressed juices processed with high pressure technology" for the European market progressively turned out to be beneficial, and HPP products have found their place with clients.

After several years, GL Foods now produces salads, hummus and soups, as well as juices, and no supermarket chain or corner shop can afford to not offer HPP cold-pressed juices, even at a price that is two or three times higher than classic pasteurized products, and even when these products are positioned close to each other on the shelves. There are buyers for both types of products and sales continue to grow.

According to Maria Ferrante, senior Director of Marketing and Communications at the APPT (Association for Packaging and Processing Technologies), in addition to the advantage of being able to display a "clean label" because they contain little or no additives, food products treated with high pressure present both an organoleptic quality that is frequently better than traditional equivalent products and a prolonged shelf-life, often two or three times longer than what can be obtained with thermal treatment techniques. These advantages lead to higher yields, which mean better profitability for processors and a significant decrease in waste.

With this technology, processors can take their production to a higher level of innovation by providing a guaranteed longer shelf-life for products like fresh fruit and vegetable juices, something that would otherwise not be possible without the joint use of heat, additives and preservatives. Prolonged shelf-life and increased food safety now go hand-in-hand with better preserved taste, color, texture and nutritional value, for food products that correspond to the expectations of consumers who want to preserve the qualities of fresh products.

Douglas Gilman explained that tomato-based products could use this technology. For about five years, his company has been making for the Spanish market a typical product that is used every day, based on fresh tomato that consumers spread onto bread with a drizzle of olive oil, similar to what a lot of companies offer in a pasteurized form.

Soups manufactured by GL Foods are another example, like gazpacho, which represents an important market and is increasingly sold around the world. It is possible to do exactly the same thing with high-pressure technology, and at a considerably higher selling price.

Today, GL Foods is present in 23 European countries. The group has been exporting its products to the USA for one year now, and has been virtually "obliged" to open a production plant in that country in order to satisfy the growing number of US clients (Walmart, HEB, Starbucks, McDo, Publix, etc.). It recently opened a factory near Philadelphia in Pennsylvania. This has led the company to shift from zero exports in 2013 to EUR 31 million in "export" turnover in 2018 (and 50 million in 2019 due to the increase in operations linked to exports to the USA). Foreign markets now absorb 70% of the output from the Portuguese factory.

Today, GL Foods is present in 23 European countries. The group has been exporting its products to the USA for one year now, and has been virtually "obliged" to open a production plant in that country in order to satisfy the growing number of US clients (Walmart, HEB, Starbucks, McDo, Publix, etc.). It recently opened a factory near Philadelphia in Pennsylvania. This has led the company to shift from zero exports in 2013 to EUR 31 million in "export" turnover in 2018 (and 50 million in 2019 due to the increase in operations linked to exports to the USA). Foreign markets now absorb 70% of the output from the Portuguese factory.

At the worldwide level, research shows that the market for food products that are made using HPP amounted to a value of USD 14 billion in 2018. In 2023, that market will reach USD 27.4 billion, and should reach USD 51.1 billion by 2027. This growth is the result of a number of factors, notably consumer trends, health safety concerns, and demand coming from the food industry.

Some complementary data

Today, GL Foods is present in 23 European countries. The group has been exporting its products to the USA for one year now, and has been virtually "obliged" to open a production plant in that country in order to satisfy the growing number of US clients (Walmart, HEB, Starbucks, McDo, Publix, etc.). It recently opened a factory near Philadelphia in Pennsylvania. This has led the company to shift from zero exports in 2013 to EUR 31 million in "export" turnover in 2018 (and 50 million in 2019 due to the increase in operations linked to exports to the USA). Foreign markets now absorb 70% of the output from the Portuguese factory.

Today, GL Foods is present in 23 European countries. The group has been exporting its products to the USA for one year now, and has been virtually "obliged" to open a production plant in that country in order to satisfy the growing number of US clients (Walmart, HEB, Starbucks, McDo, Publix, etc.). It recently opened a factory near Philadelphia in Pennsylvania. This has led the company to shift from zero exports in 2013 to EUR 31 million in "export" turnover in 2018 (and 50 million in 2019 due to the increase in operations linked to exports to the USA). Foreign markets now absorb 70% of the output from the Portuguese factory.