FENCO Food Machinery has been awarded a new turn-key installation and commissioning of tomato paste equipment for Norjax Canning pty factory, Limpopo (South Africa).

After Cape Concentrate project in Cape Town, a multimillion euros facility all manufactured by

FENCO Food Machinery, the Italian firm has been awarded another huge tender for the whole commissioning of tomato processing equipment for the transformation of 750 tons/day of fresh tomatoes in hot/cold break tomato paste packed in aseptic drums. The equipment will be delivered in May 2019 to start processing tomatoes in October 2019.

With over 35 years of experience,

FENCO Food Machinery continues its journey with the aim to be the first to innovate tomato processing. Focusing on the tomato processing in all its meanings,

FENCO Food Machinery has constantly expanded its technical and product portfolio with innovative solutions, providing a superior technology and service to the world’s largest tomato processors.

Always focusing on how to maximize the yields and the efficiency, and to minimize the water, steam and power consumption, the

FENCO Food Machinery equipment includes certain important features, such as:

- product evaporation temperature (max. 75°C) in the first effect

- high product speed inside heat exchangers due to oversized pumps and motors

- upward product circulation inside evaporator’s heat exchangers in order to reduce fouling problems thus extending running time without cleaning

- overall minimum water consumption

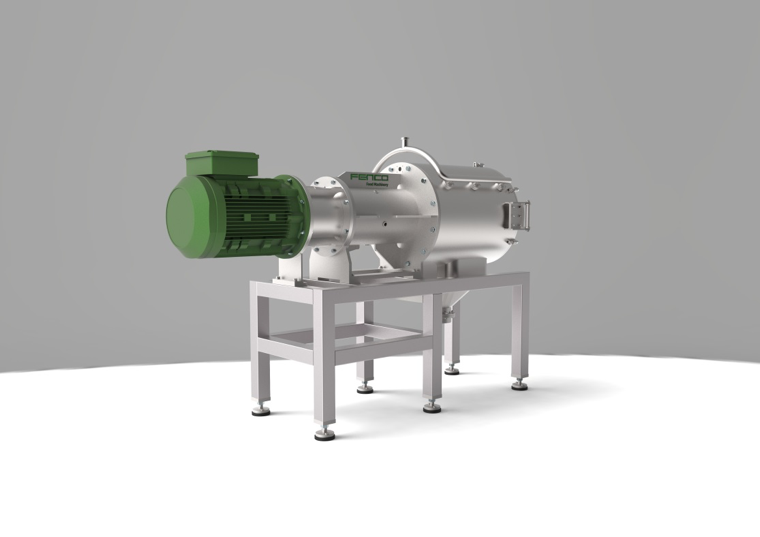

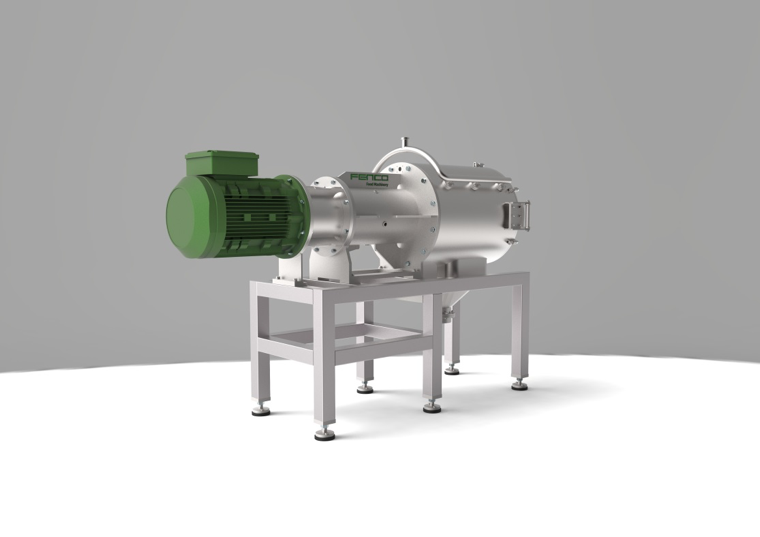

The production of tomato juice always starts by fresh tomatoes, well ripe, having red sharp colour, free from skin and seeds, duly chopped, pulped and refined. So

FENCO Food Machinery has developed a new juice extraction group, consisting of pulper and refiner (finisher) assembled on the same structure of the evaporator. The new turbo extractor is based on a conical rotor with 20 straight blades, single direction of rotation and adjustable rotor-sieve clearance for amazing yields and performances.

The project of course includes high speed self cleaning hot break/cold break vertical type system. The equipment is able to process over 40 tons/hour and its main function is the inactivation of the pectolytic enzymes when working at hot break (95°C) or pre-heating of the chopped tomatoes (70°C) when working at cold break.

Working at hot break the equipment will be able to increase the yields of the juice extraction process, to reduce or partially eliminate the syneresis phenomena of concentrated product, and to increase the consistency of the final concentrated product due to the total inactivation of the pectin agents.

The evaporation takes place under vacuum in the

FENCO Food Machinery triple effect/three stages evaporator. The tomato juice goes on counter-current flow with vapours, in fact juice enters the system from the hot break unit where the enzymes deactivation takes place; then from the hot break the juice is pumped into juice extractors and further into the evaporator 3rd effect where a flash evaporation as well as deaeration takes place. Inside the evaporator the juice is gradually concentrated by passing from stage 1 through stage 3 (the finisher) where is finally extracted at 30°Brix (hot break) or 38°Brix (cold break).

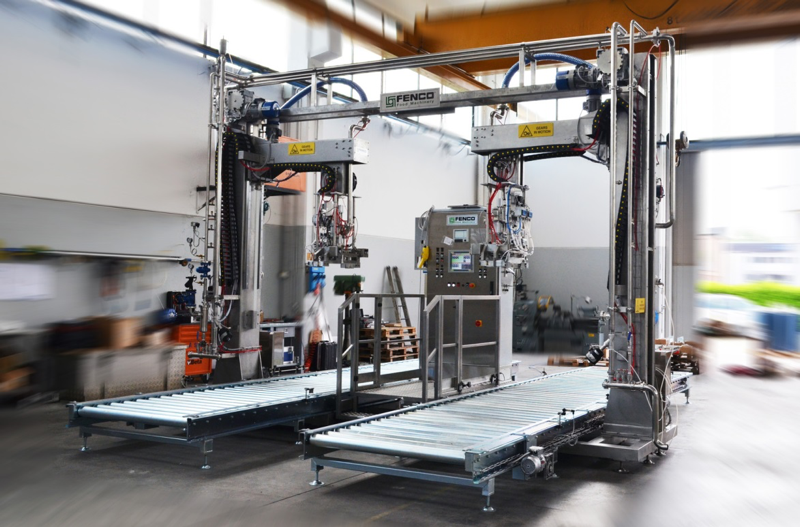

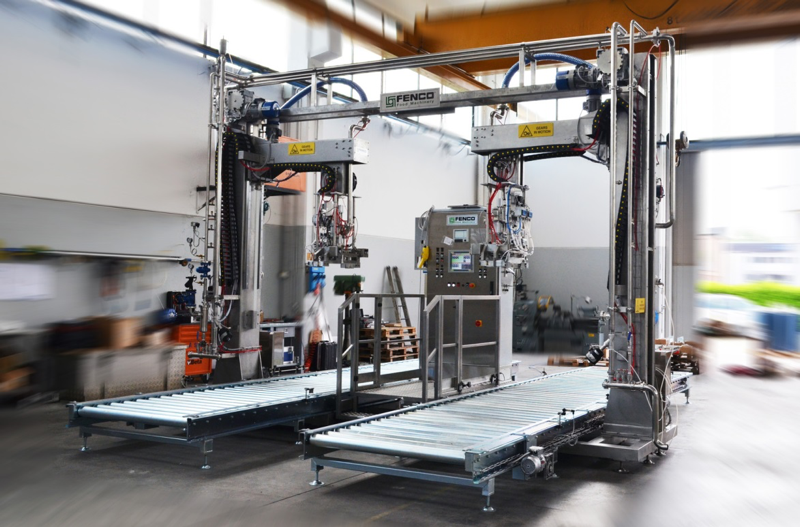

The final tomato paste is then aseptically sterilized by the

FENCO Food Machinery sterilizer/cooler and then packed in aseptic drums and bins through the

FENCO Food Machinery aseptic twin head filler with its incredible capacity over 13 tons/hour of tomato paste.

www.fenco.it

#fencofoodmachinery

#foodfutureinnovation

With over 35 years of experience, FENCO Food Machinery continues its journey with the aim to be the first to innovate tomato processing. Focusing on the tomato processing in all its meanings, FENCO Food Machinery has constantly expanded its technical and product portfolio with innovative solutions, providing a superior technology and service to the world’s largest tomato processors.

With over 35 years of experience, FENCO Food Machinery continues its journey with the aim to be the first to innovate tomato processing. Focusing on the tomato processing in all its meanings, FENCO Food Machinery has constantly expanded its technical and product portfolio with innovative solutions, providing a superior technology and service to the world’s largest tomato processors.

The evaporation takes place under vacuum in the FENCO Food Machinery triple effect/three stages evaporator. The tomato juice goes on counter-current flow with vapours, in fact juice enters the system from the hot break unit where the enzymes deactivation takes place; then from the hot break the juice is pumped into juice extractors and further into the evaporator 3rd effect where a flash evaporation as well as deaeration takes place. Inside the evaporator the juice is gradually concentrated by passing from stage 1 through stage 3 (the finisher) where is finally extracted at 30°Brix (hot break) or 38°Brix (cold break).

The evaporation takes place under vacuum in the FENCO Food Machinery triple effect/three stages evaporator. The tomato juice goes on counter-current flow with vapours, in fact juice enters the system from the hot break unit where the enzymes deactivation takes place; then from the hot break the juice is pumped into juice extractors and further into the evaporator 3rd effect where a flash evaporation as well as deaeration takes place. Inside the evaporator the juice is gradually concentrated by passing from stage 1 through stage 3 (the finisher) where is finally extracted at 30°Brix (hot break) or 38°Brix (cold break).