Respect for your privacy is our priority

The cookie is a small information file stored in your browser each time you visit our web page.Cookies are useful because they record the history of your activity on our web page. Thus, when you return to the page, it identifies you and configures its content based on your browsing habits, your identity and your preferences.

You may accept cookies or refuse, block or delete cookies, at your convenience. To do this, you can choose from one of the options available on this window or even and if necessary, by configuring your browser.

If you refuse cookies, we can not guarantee the proper functioning of the various features of our web page.

For more information, please read the COOKIES INFORMATION section on our web page.

A clear distinction must therefore be made between biodegradable plastics and plastics containing additives such as oxo-degradable plastics and enzyme-degradable plastics. The complete biodegradability of a material used in and on soil is crucial to being able to claim compliance with standards such as EN 17033 (2018). The enrichment of conventional plastics with specific additives facilitates fragmentation into smaller pieces. However, if complete biodegradation does not take place, it will lead to a build-up. Furthermore, collection for recycling will no longer be possible. In order to prevent microplastics from escaping and posing a risk to the environment, legal action is currently underway in Europe to implement specific restrictions on products intended for consumers and professionals. In addition to Directive 2019/904 and the ECHA proposal relating to oxo-degradable plastics, it should be noted that biodegradable plastics are also being targeted for more restrictive regulations. For uses where well-established collection and good waste management schemes are in place, biodegradable plastics are not the best solution. However, for some products, such as mulch films, biodegradable plastics may be considered an interesting option.

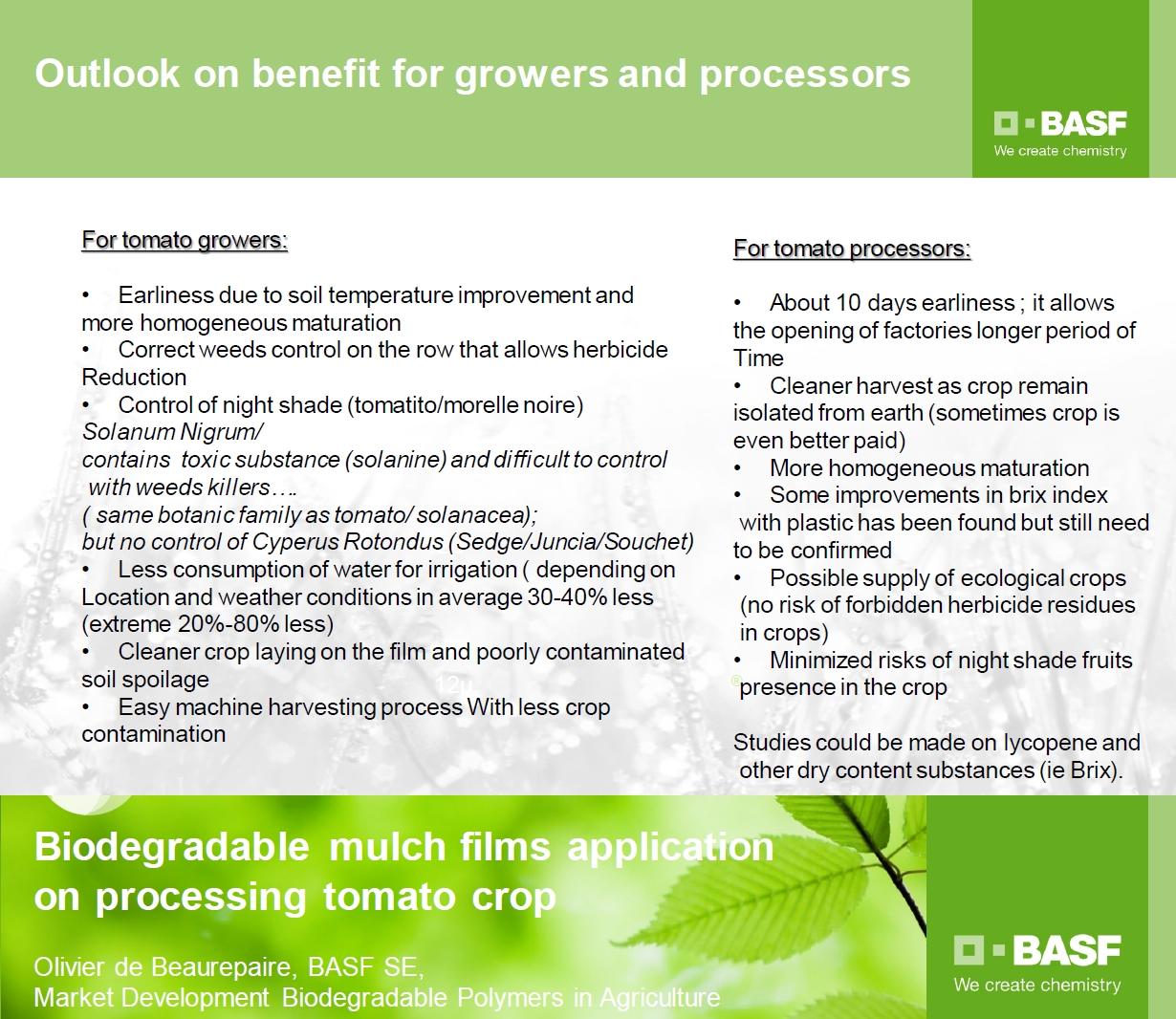

A clear distinction must therefore be made between biodegradable plastics and plastics containing additives such as oxo-degradable plastics and enzyme-degradable plastics. The complete biodegradability of a material used in and on soil is crucial to being able to claim compliance with standards such as EN 17033 (2018). The enrichment of conventional plastics with specific additives facilitates fragmentation into smaller pieces. However, if complete biodegradation does not take place, it will lead to a build-up. Furthermore, collection for recycling will no longer be possible. In order to prevent microplastics from escaping and posing a risk to the environment, legal action is currently underway in Europe to implement specific restrictions on products intended for consumers and professionals. In addition to Directive 2019/904 and the ECHA proposal relating to oxo-degradable plastics, it should be noted that biodegradable plastics are also being targeted for more restrictive regulations. For uses where well-established collection and good waste management schemes are in place, biodegradable plastics are not the best solution. However, for some products, such as mulch films, biodegradable plastics may be considered an interesting option. The EN 17033 standard defines the characteristics of biodegradable film in the field, including the duration of use by type of crop. On a technical level, a film (polymer + plasticizer + filler (starch or chalk)) that is biodegradable, and conventional polyethylene to which no stabilizer has been added, degrade the moment they are manufactured – in fact plastic is naturally biodegradable. The effective lifespan of a plastic is directly conditioned by the nature and quantity of stabilizing product it contains (determined to withstand a given quantity of thermal radiation (degree days) and light radiation (kilolumens). It remains an obvious fact that weather conditions are difficult to predict. The nature of the soil and especially the microbial activity (degradation of polylactic acid (starch) which makes up the plastic) also play an important role, causing variations in the degradation speed of the mulch. However, all mulches do not degrade in the same way, depending in particular on the compositions linked to the different colors used. In the increasingly green context of European agricultural policy, colorless "crystal" mulch remains "politically incorrect" insofar as it must contain an anti-UV additive (traces (a few ppm) of component based on metal oxides). However, this type of mulch film is not used for processing tomato crops, as its use is reserved for the melon sector.

The EN 17033 standard defines the characteristics of biodegradable film in the field, including the duration of use by type of crop. On a technical level, a film (polymer + plasticizer + filler (starch or chalk)) that is biodegradable, and conventional polyethylene to which no stabilizer has been added, degrade the moment they are manufactured – in fact plastic is naturally biodegradable. The effective lifespan of a plastic is directly conditioned by the nature and quantity of stabilizing product it contains (determined to withstand a given quantity of thermal radiation (degree days) and light radiation (kilolumens). It remains an obvious fact that weather conditions are difficult to predict. The nature of the soil and especially the microbial activity (degradation of polylactic acid (starch) which makes up the plastic) also play an important role, causing variations in the degradation speed of the mulch. However, all mulches do not degrade in the same way, depending in particular on the compositions linked to the different colors used. In the increasingly green context of European agricultural policy, colorless "crystal" mulch remains "politically incorrect" insofar as it must contain an anti-UV additive (traces (a few ppm) of component based on metal oxides). However, this type of mulch film is not used for processing tomato crops, as its use is reserved for the melon sector.